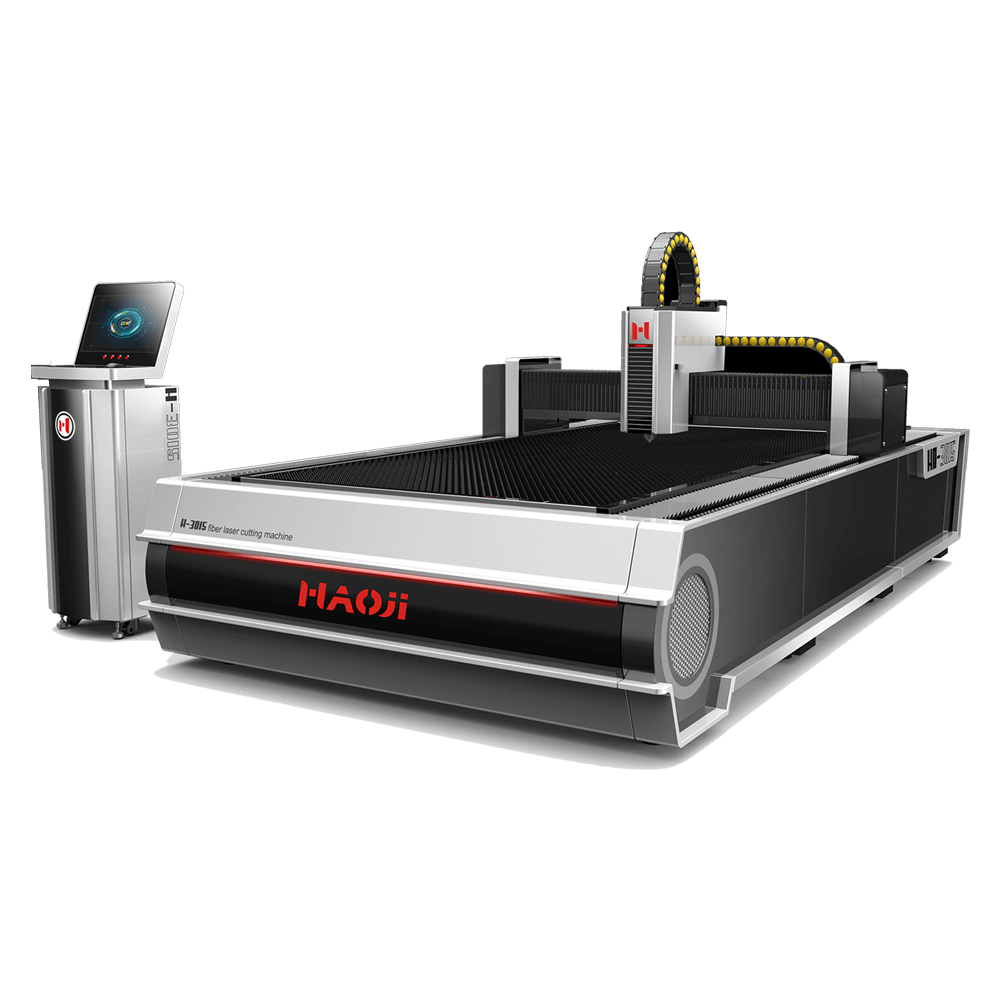

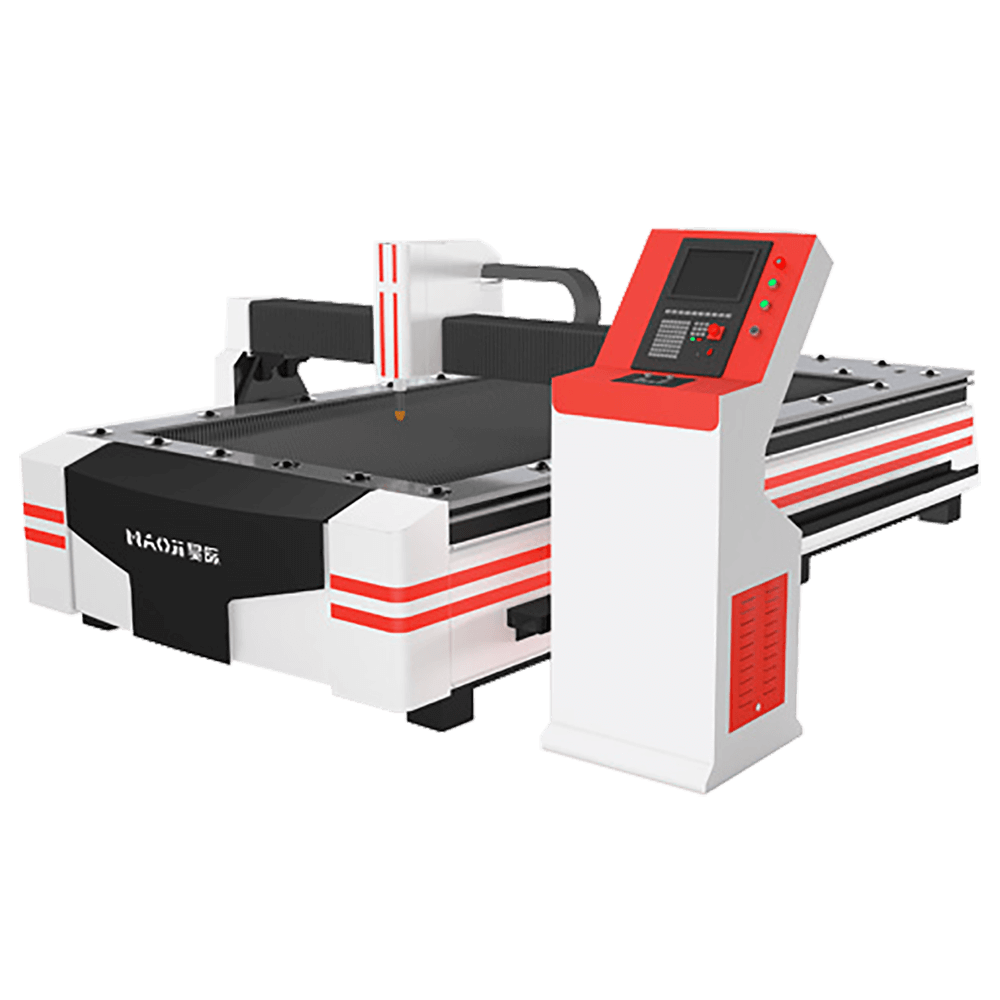

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

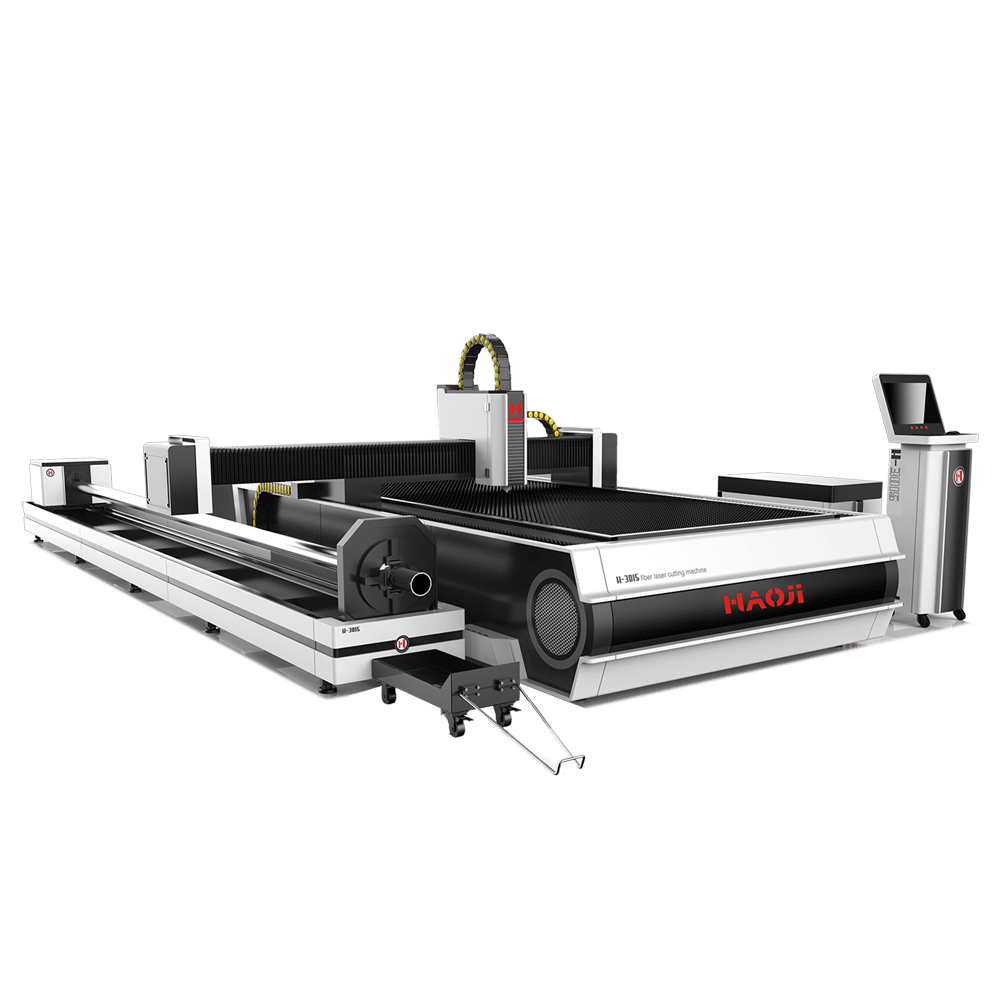

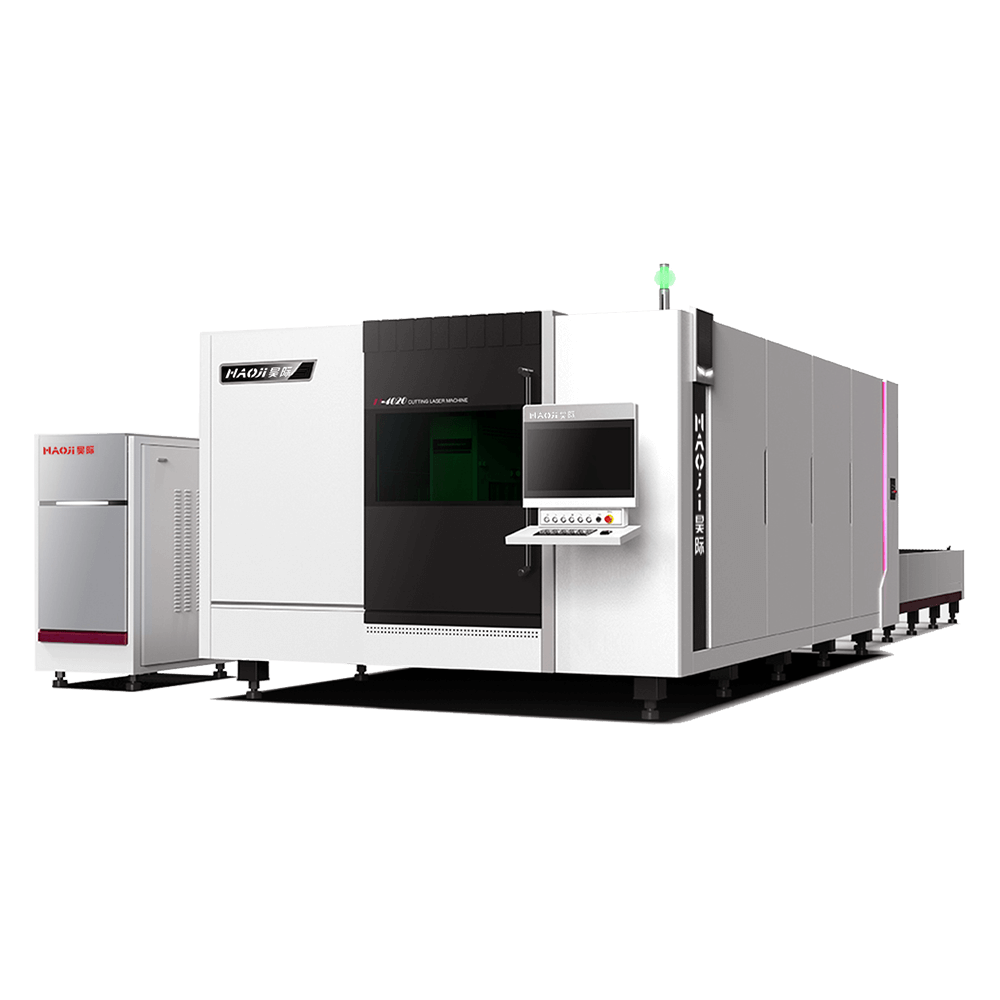

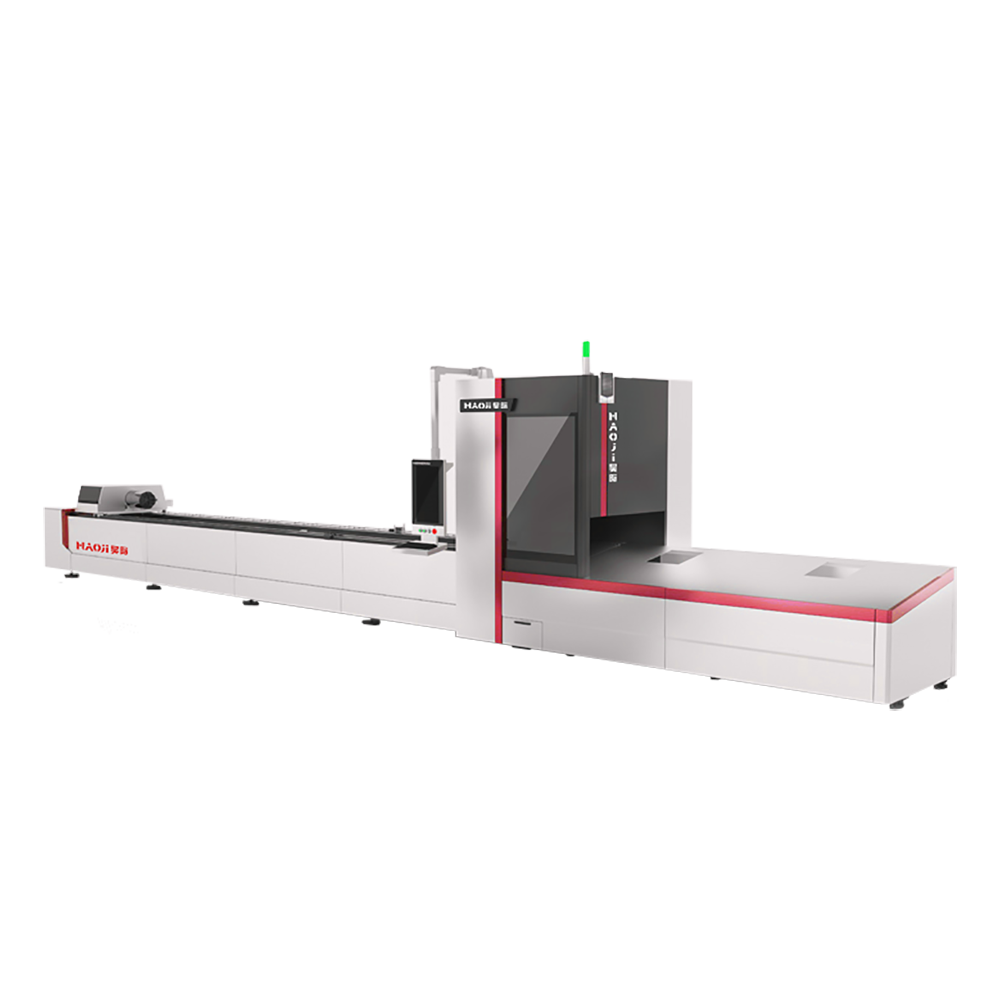

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

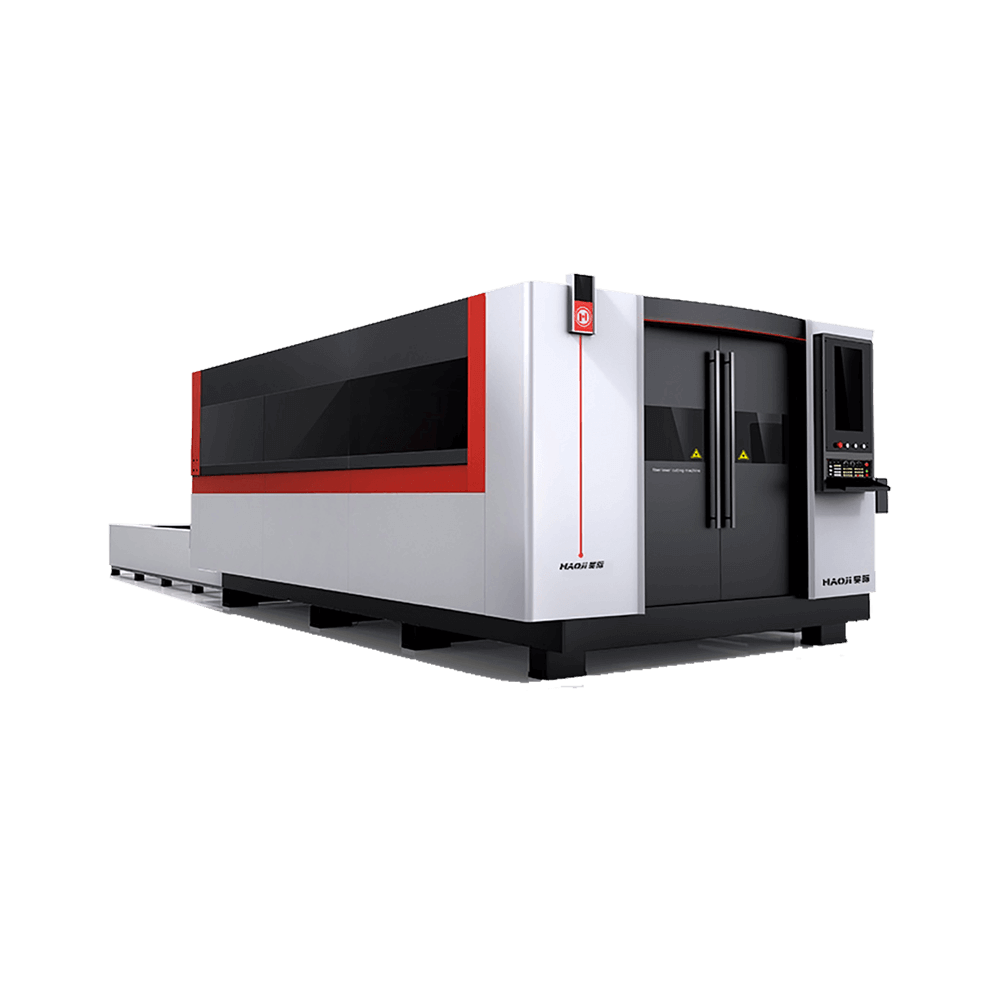

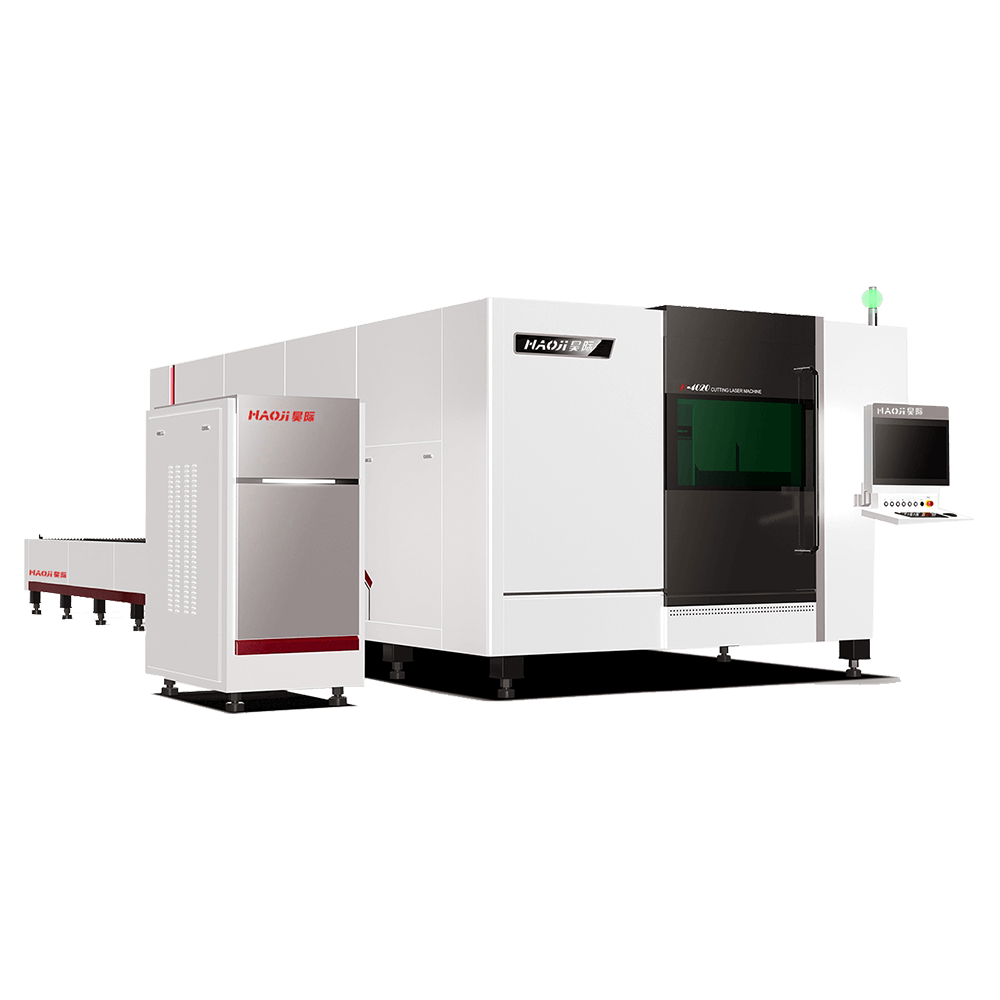

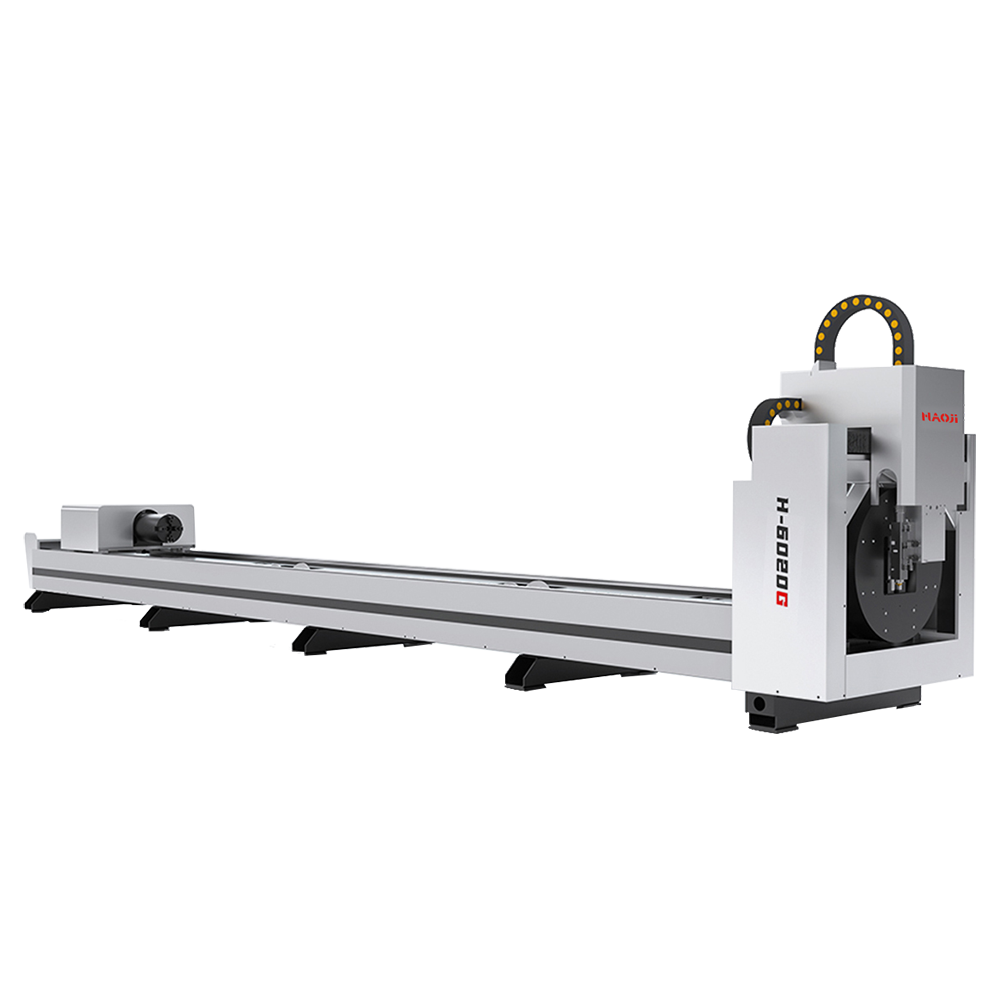

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

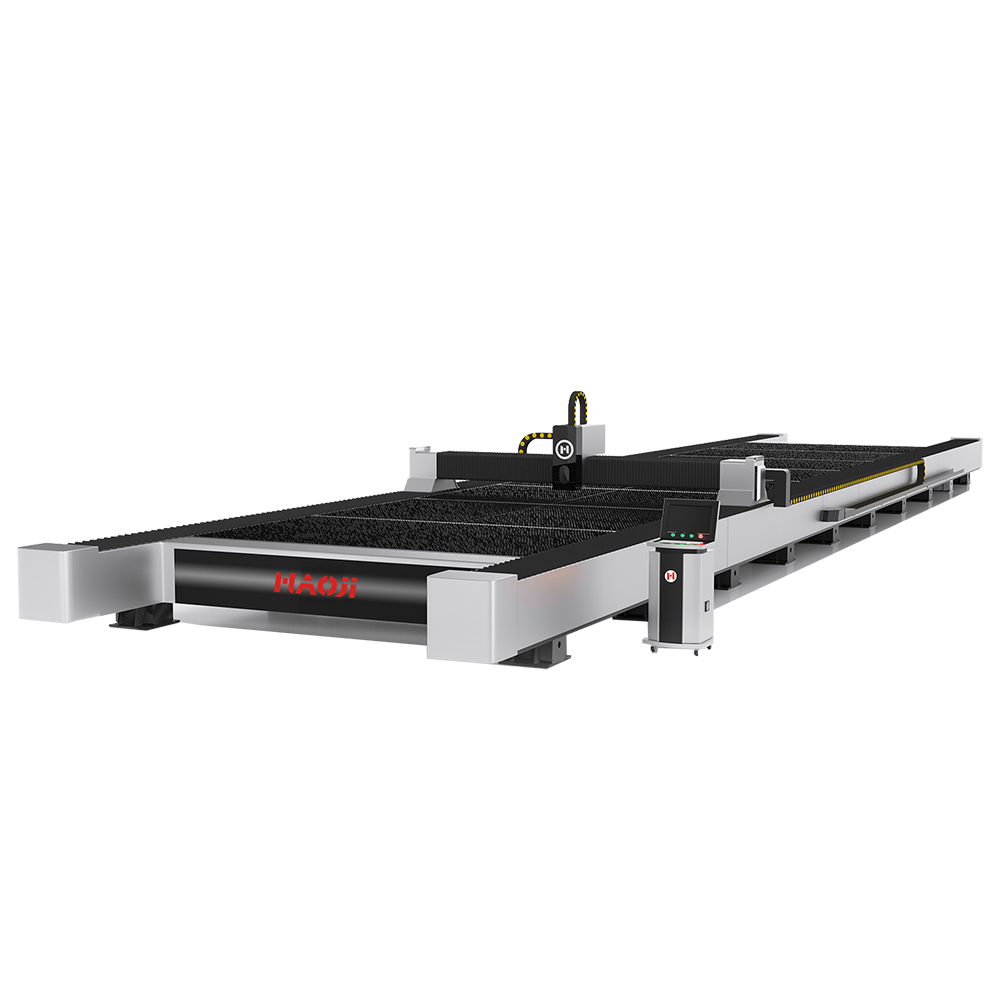

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

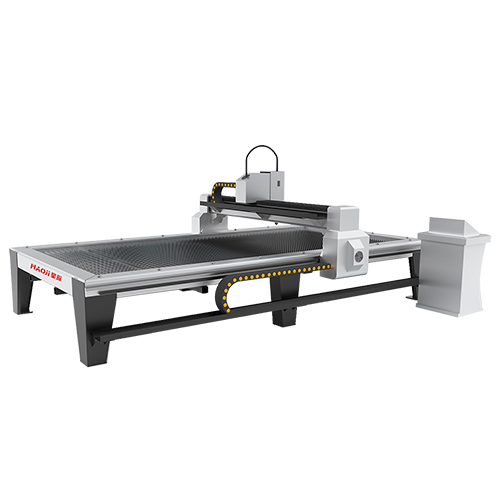

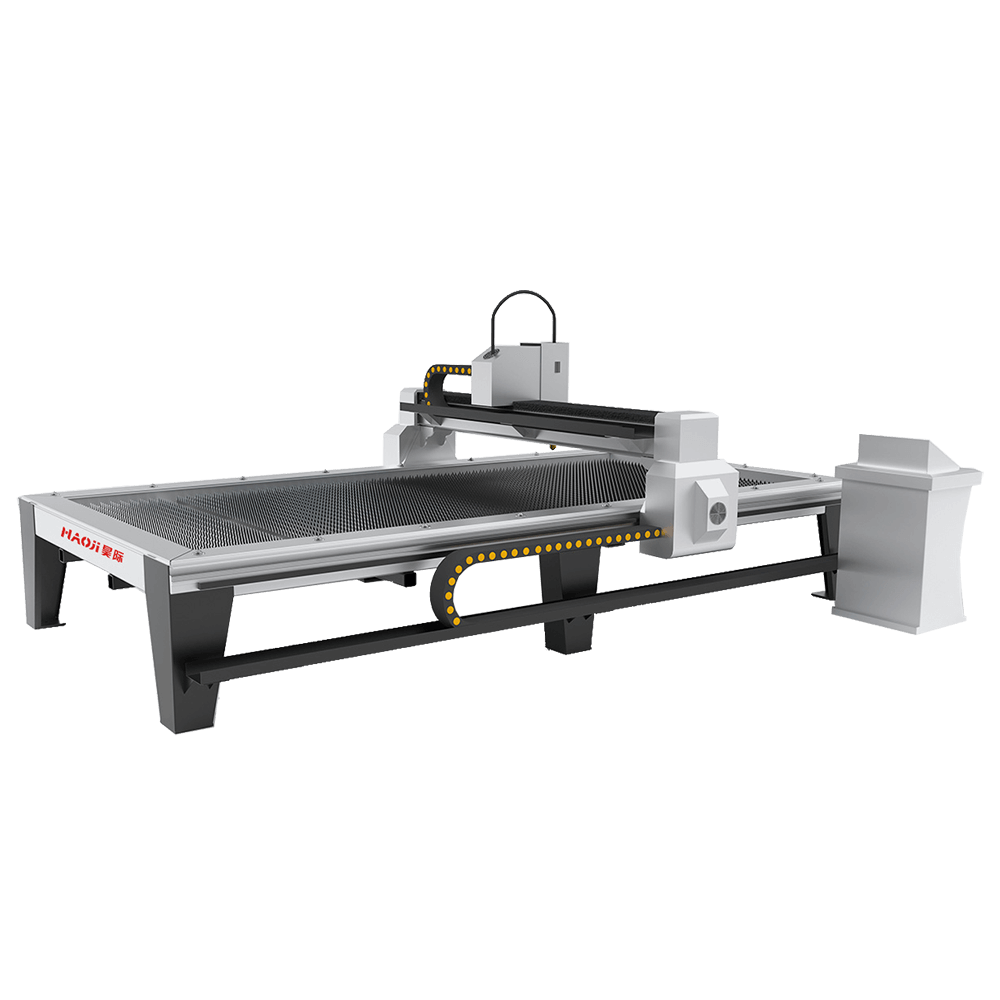

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

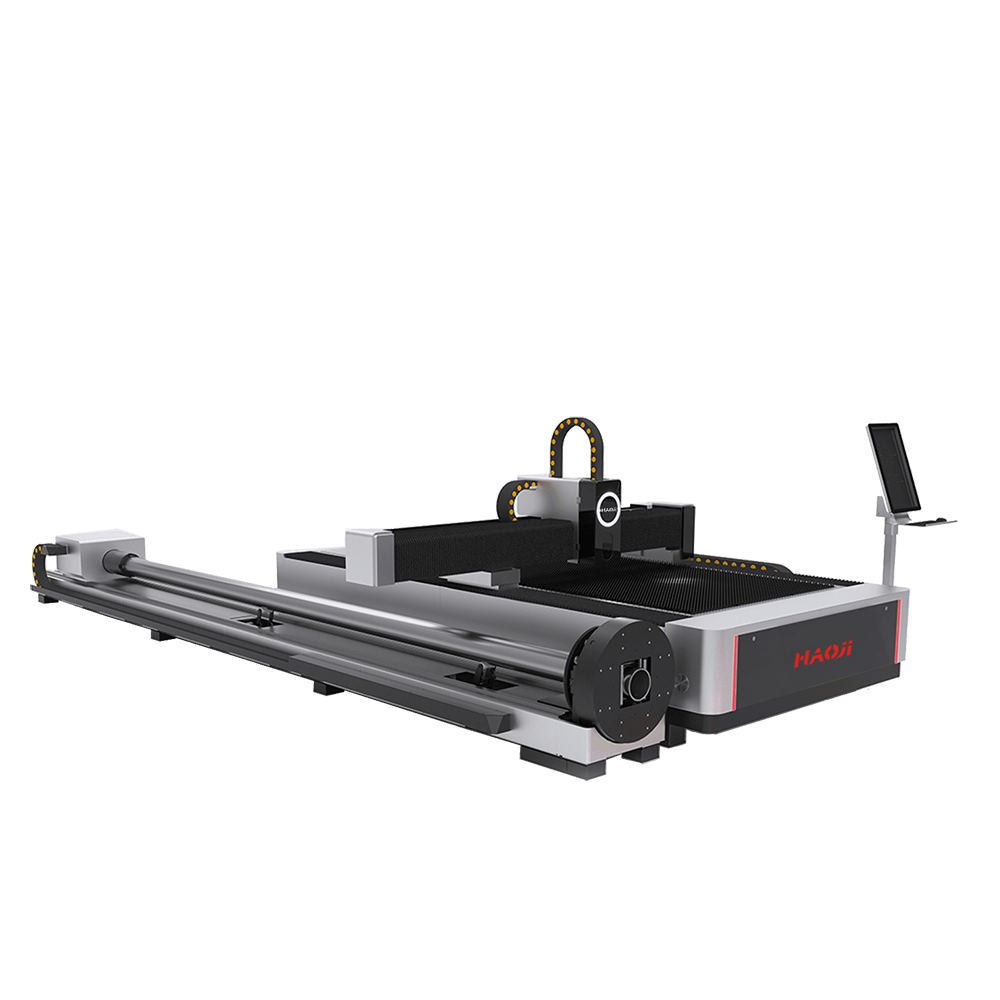

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

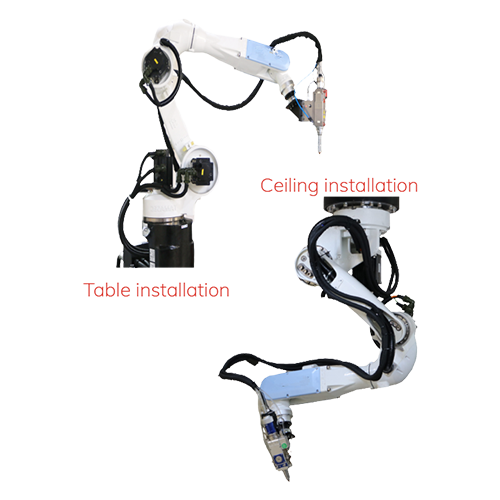

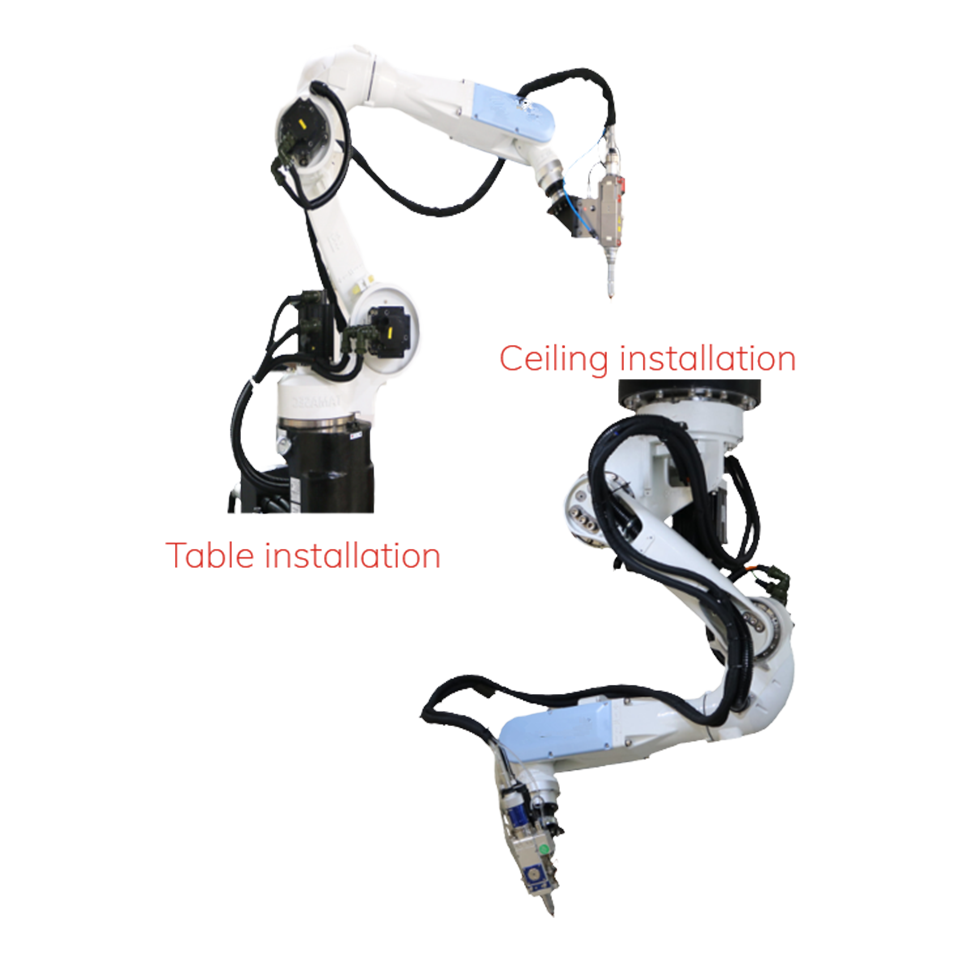

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

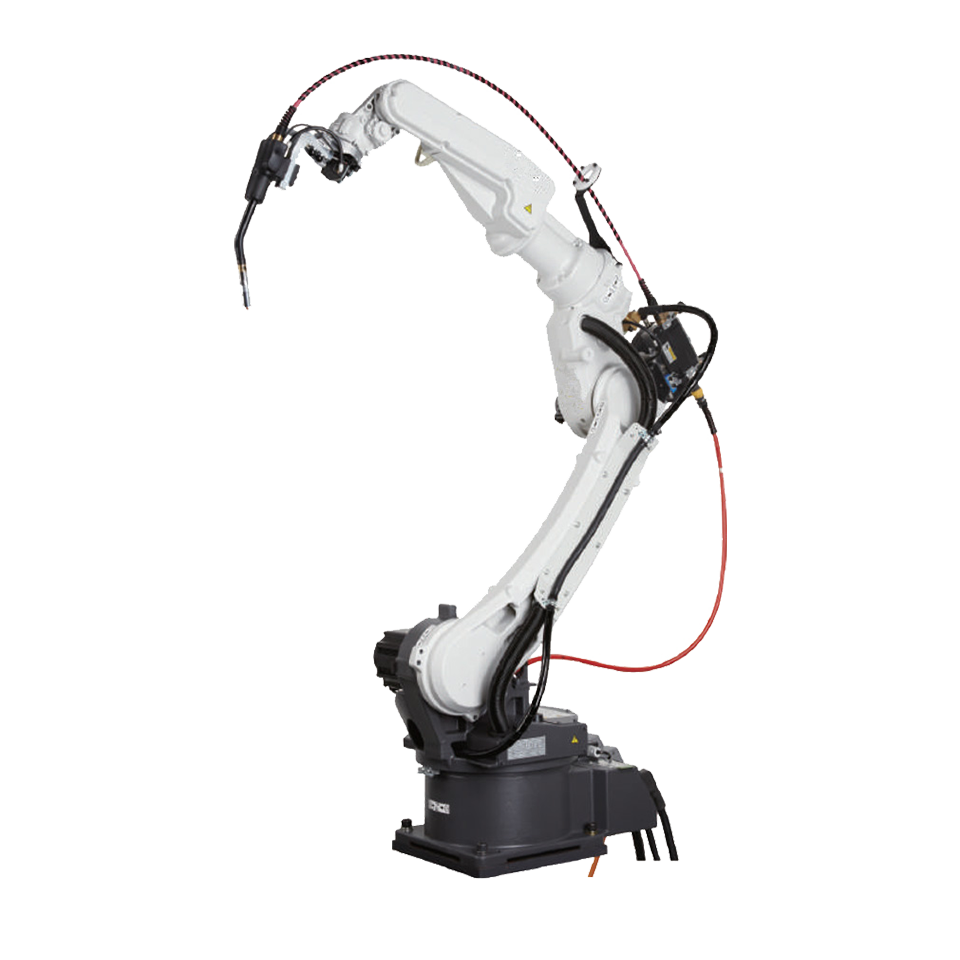

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:07-22 2021

In order to ensure the quality of fiber laser cutting machine, we have to learn more maintenance guide.

Here are some tips for cleaning and maintenance of machine tool transmission part:

1.Z axis guide rails and lead screws are cleaned with a clean cloth every month. After cleaning, apply appropriate amount of lubricant manually. (Mobil01# Lithium Base Grease Butter)

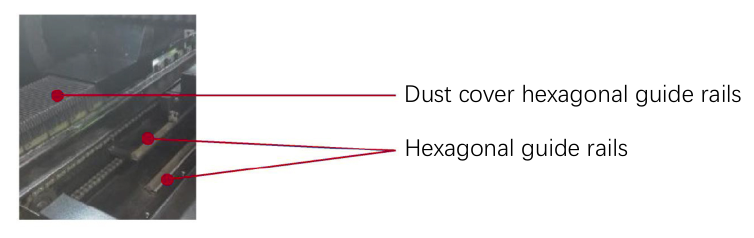

2. Check the integrity and stability of the dust cover every day, and clean the dust cover, iron filings, iron blocks and other foreign objects on the dust cover, hexagonal guide rails.

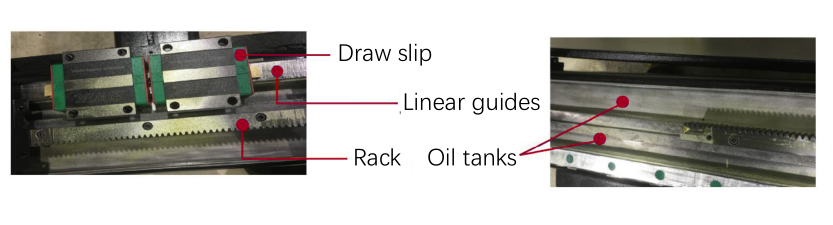

3. Clean the X, Y axis gears, racks, linear guides, oil tanks, etc. every half month, and add oil for maintenance

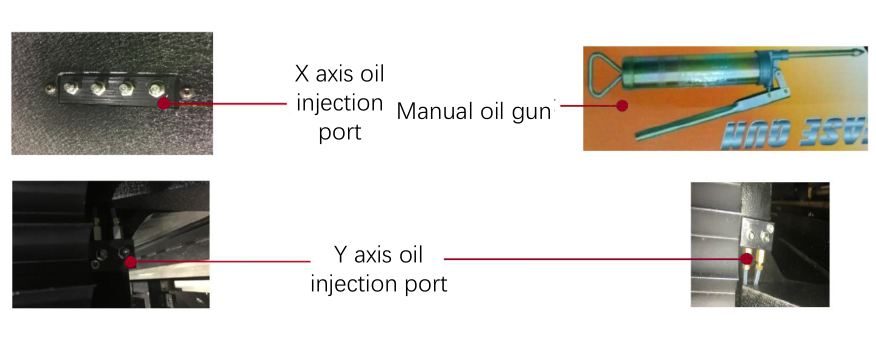

4. Use a manual grease gun to add lithium-based grease to the X and Y-axis sliders every half month, and move them back and forth at a slow speed to ensure the normal lubrication of the sliders; and add oil to the Z-axis screw and guide rail slider; When use manual oil gun refueling, aim at the oil injection port of the machine once every 15 days and apply the oil once, 30 times each time, please use Mobil 01# Lithium Base Grease Butter.

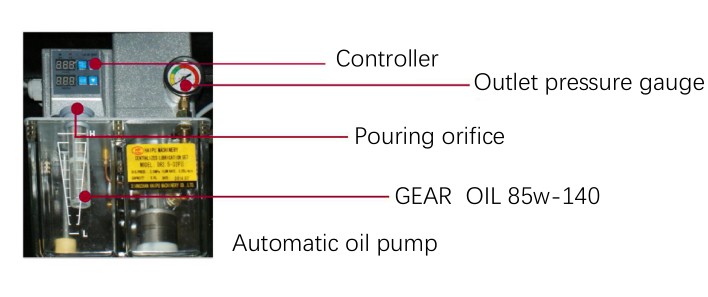

5. Regularly check the amount of lubricating oil and add lubricating oil in time.

This equipment is a dual lubrication system. The rack uses an automatic oil pump to refuel. If the oil volume of the automatic oil pump is too low, the system will give an alarm. Please use MOBIL DELVAC GEAR OIL 85w-140 to refill the oil. Then reset it.

For more maintenance guide of fiber laser cutting machine, feel free to contact us, or visit our website.