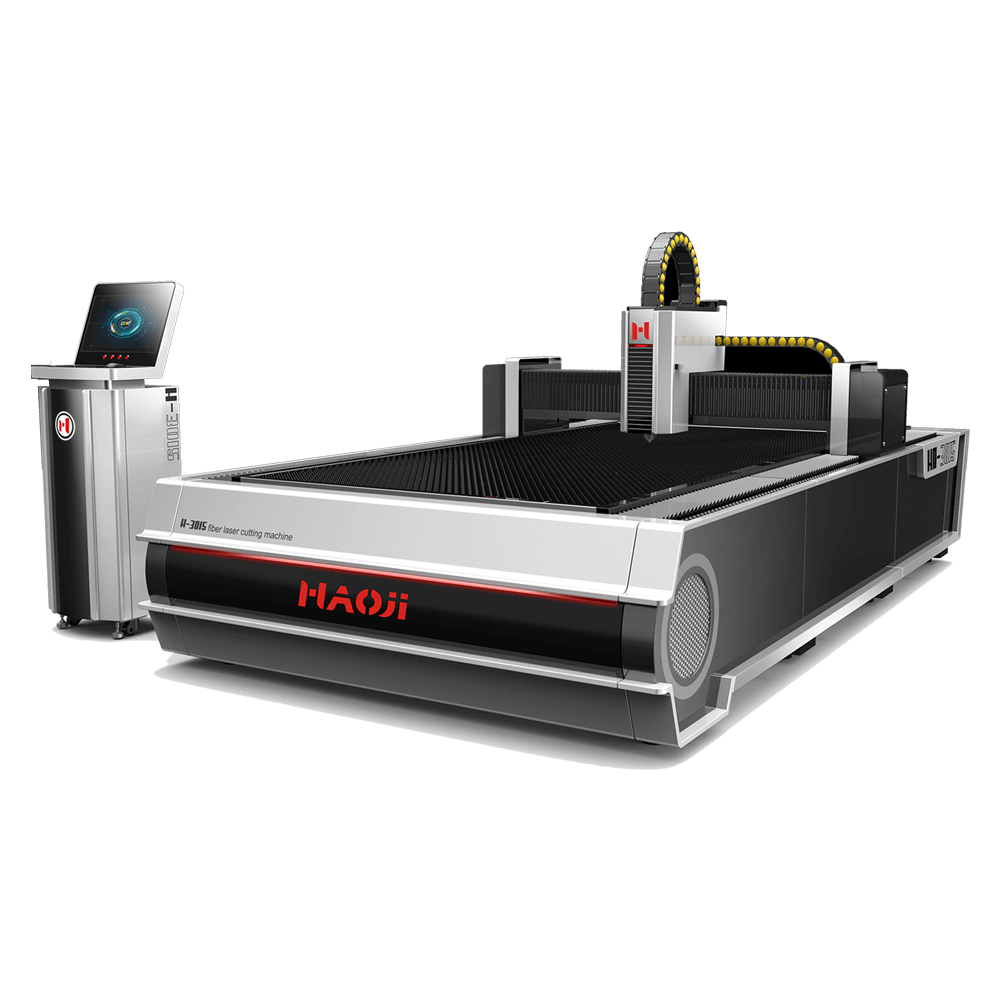

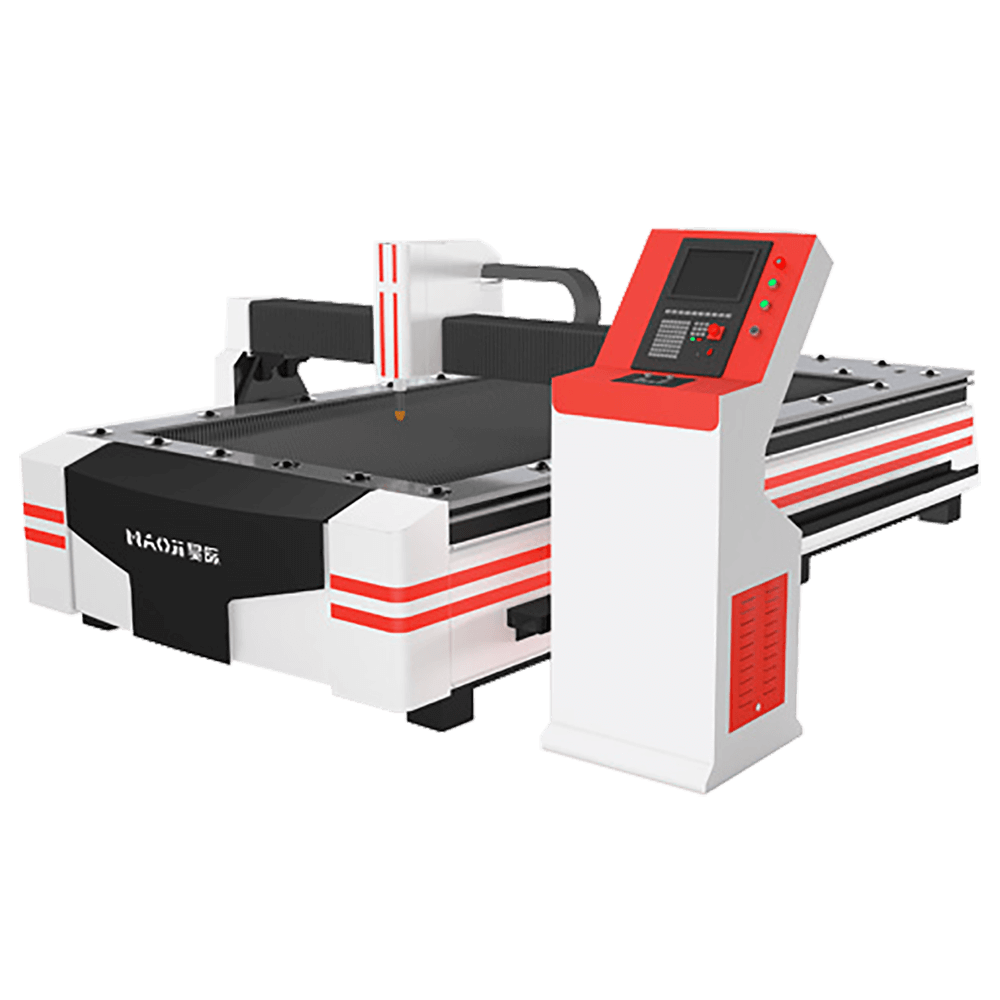

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

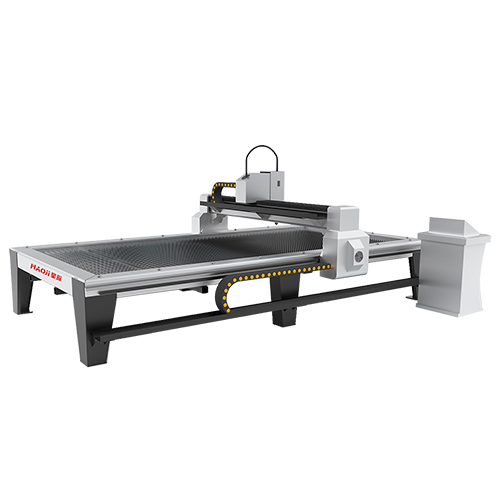

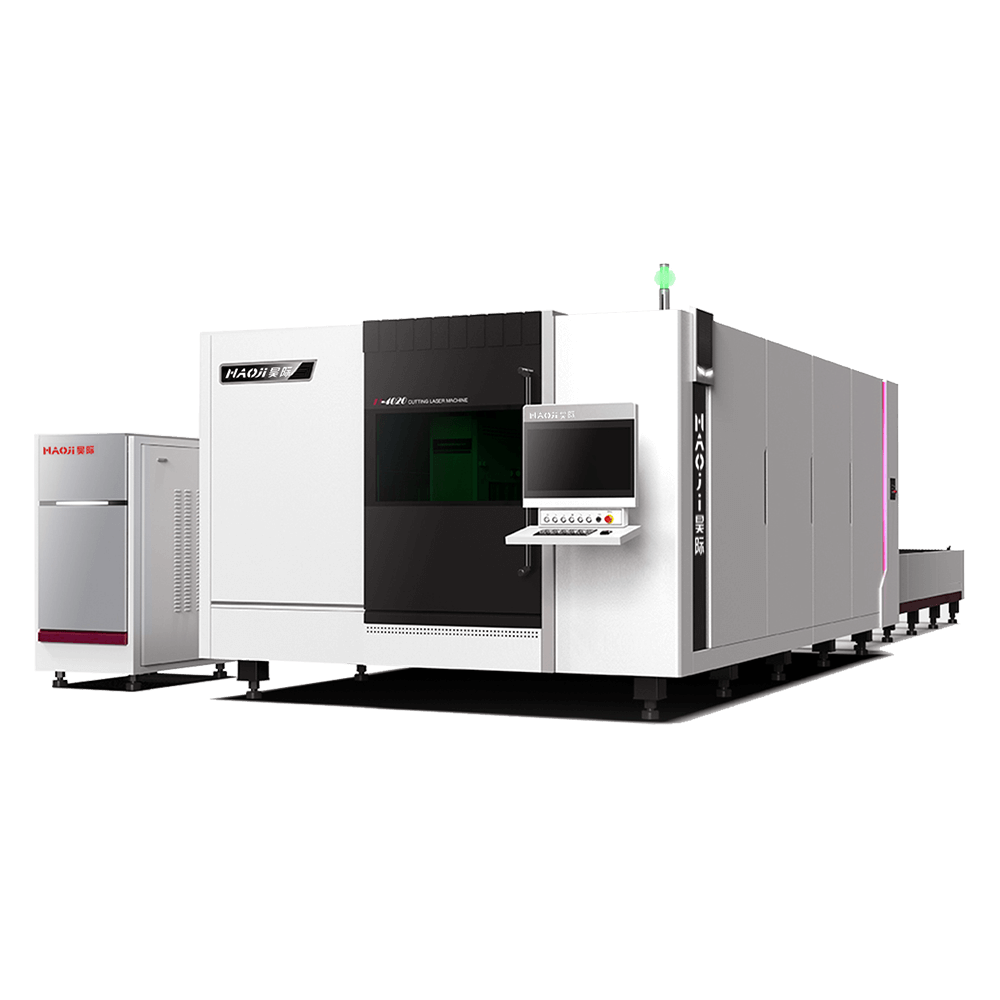

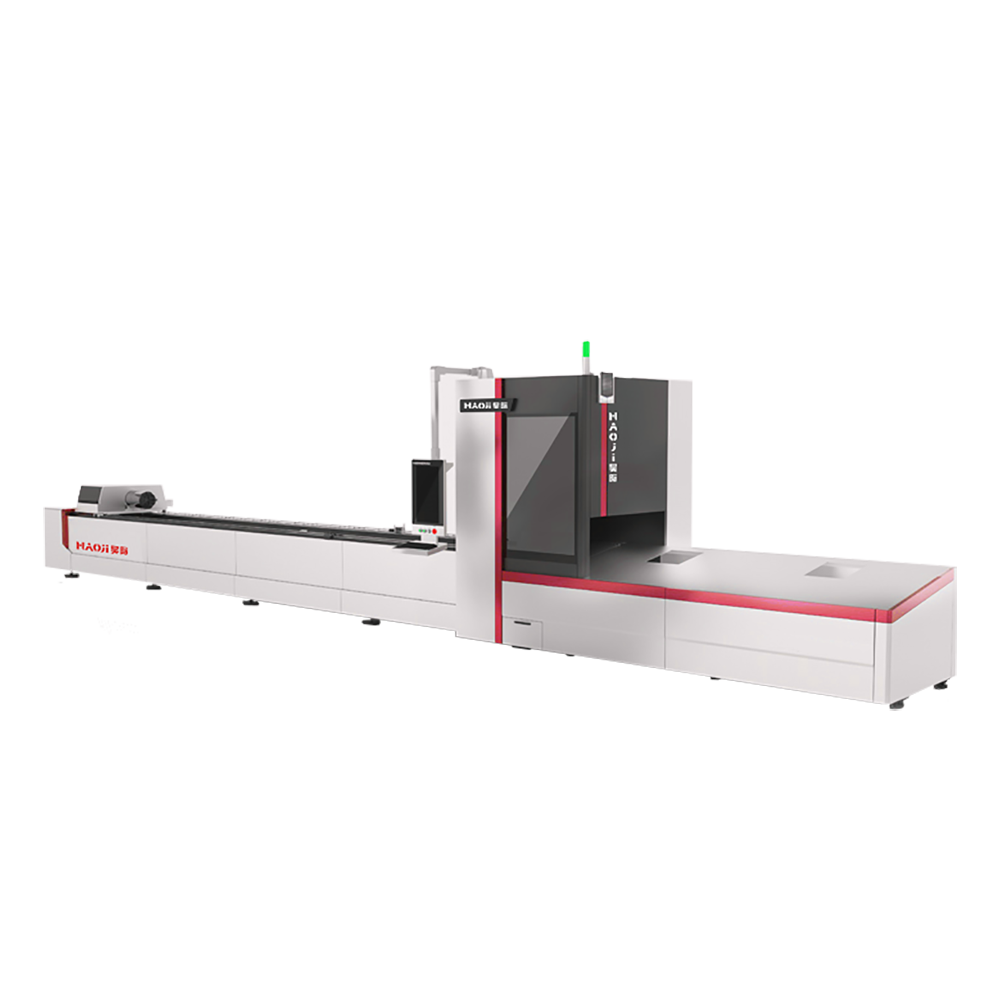

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

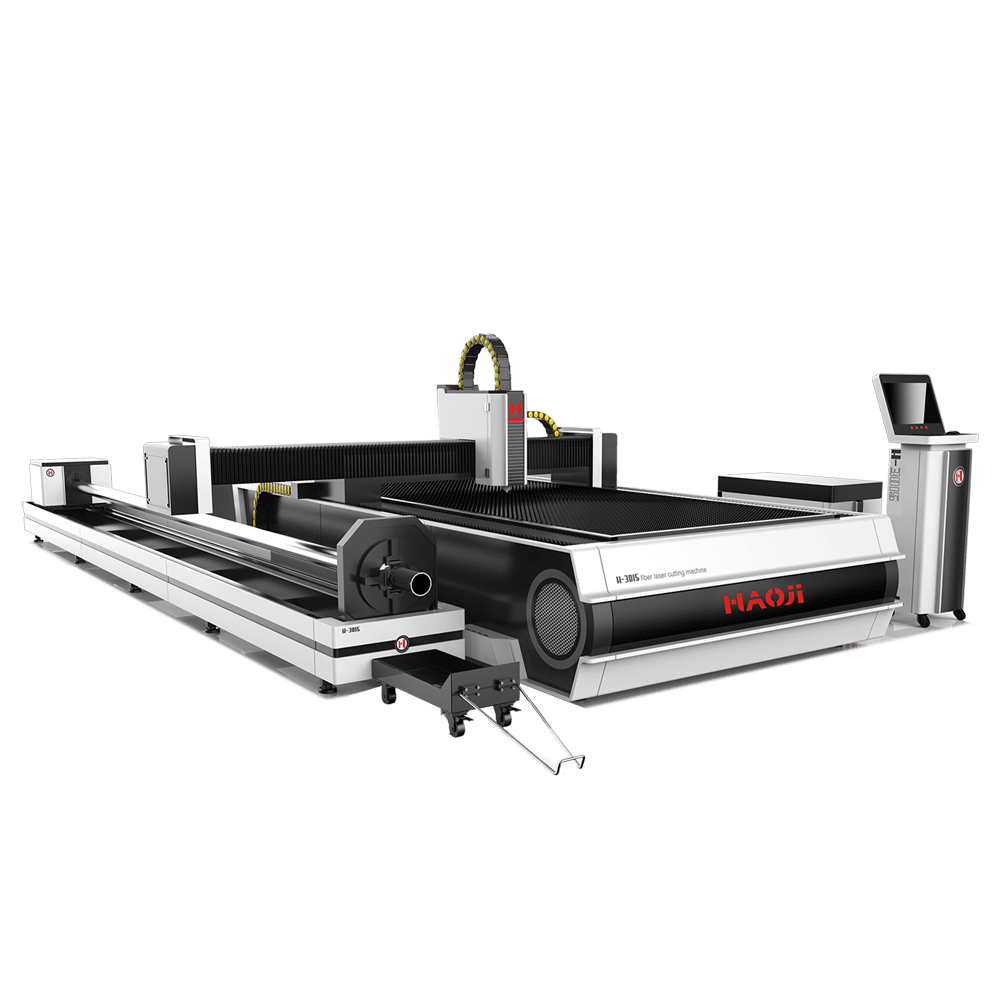

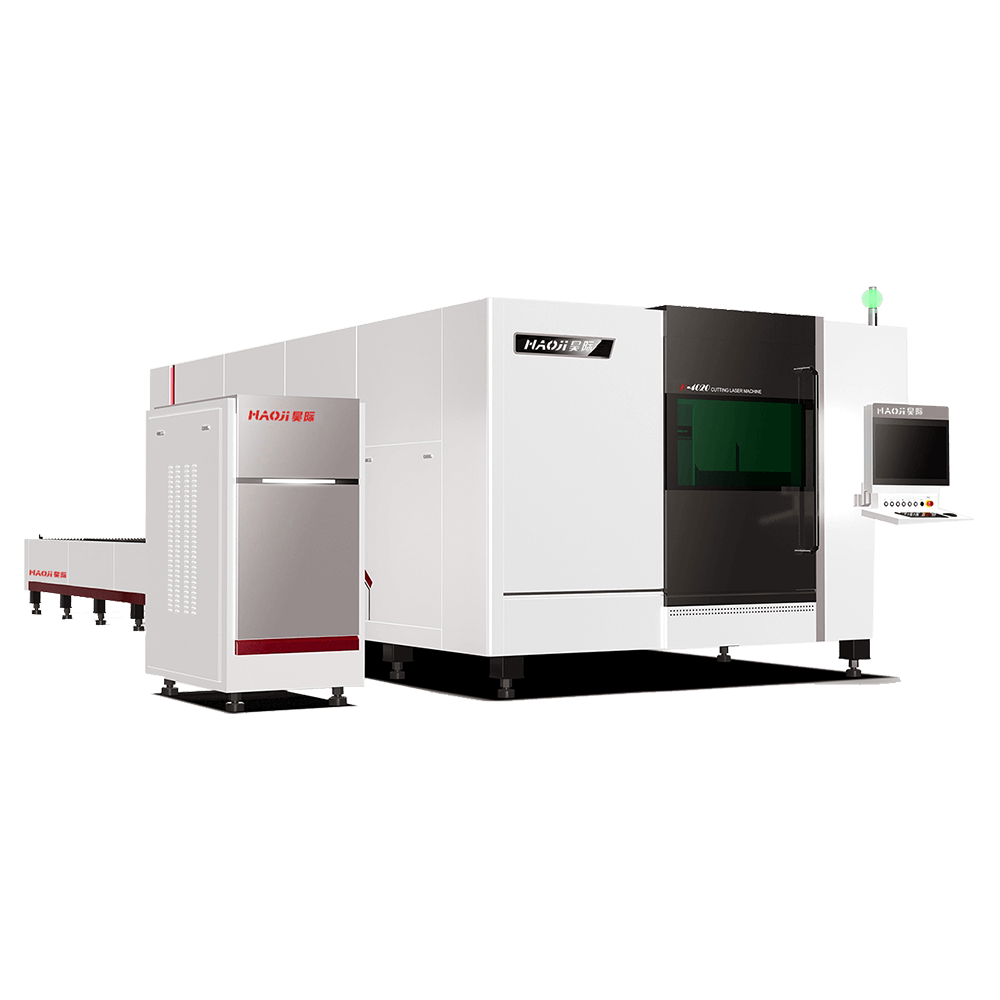

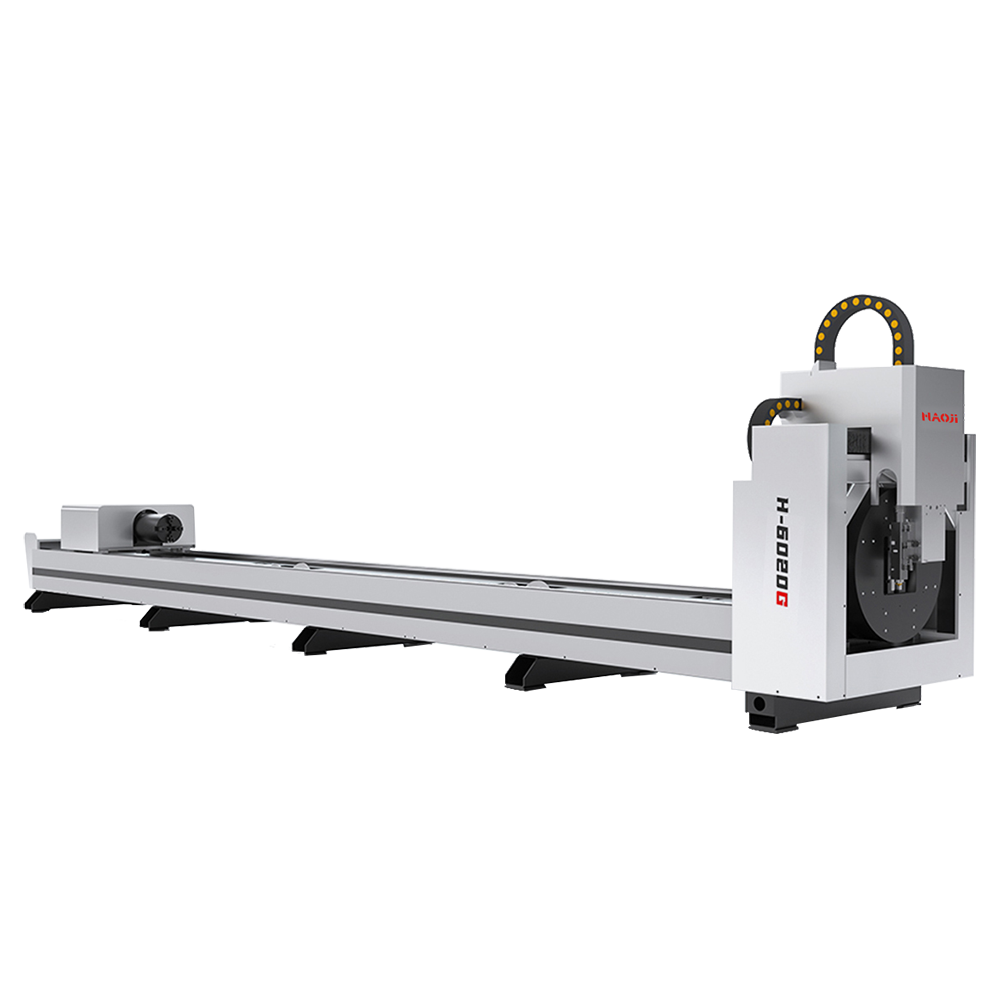

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

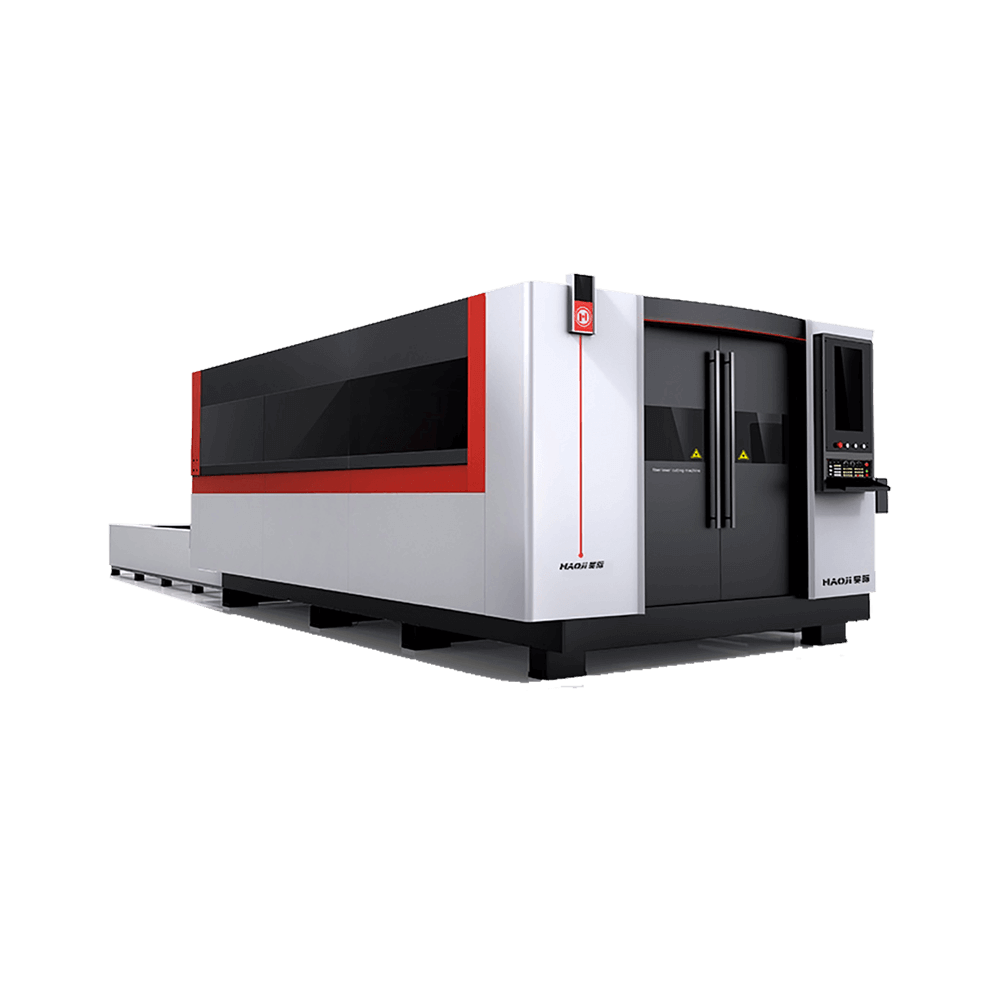

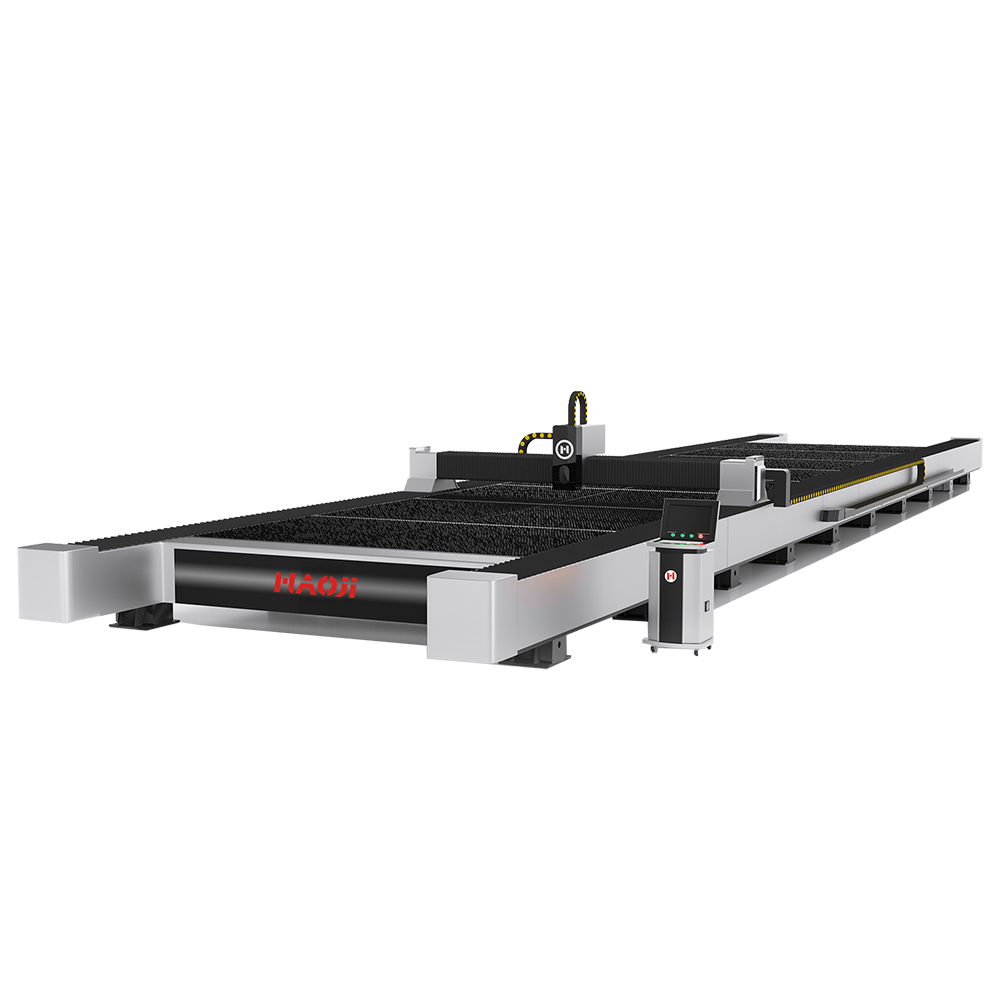

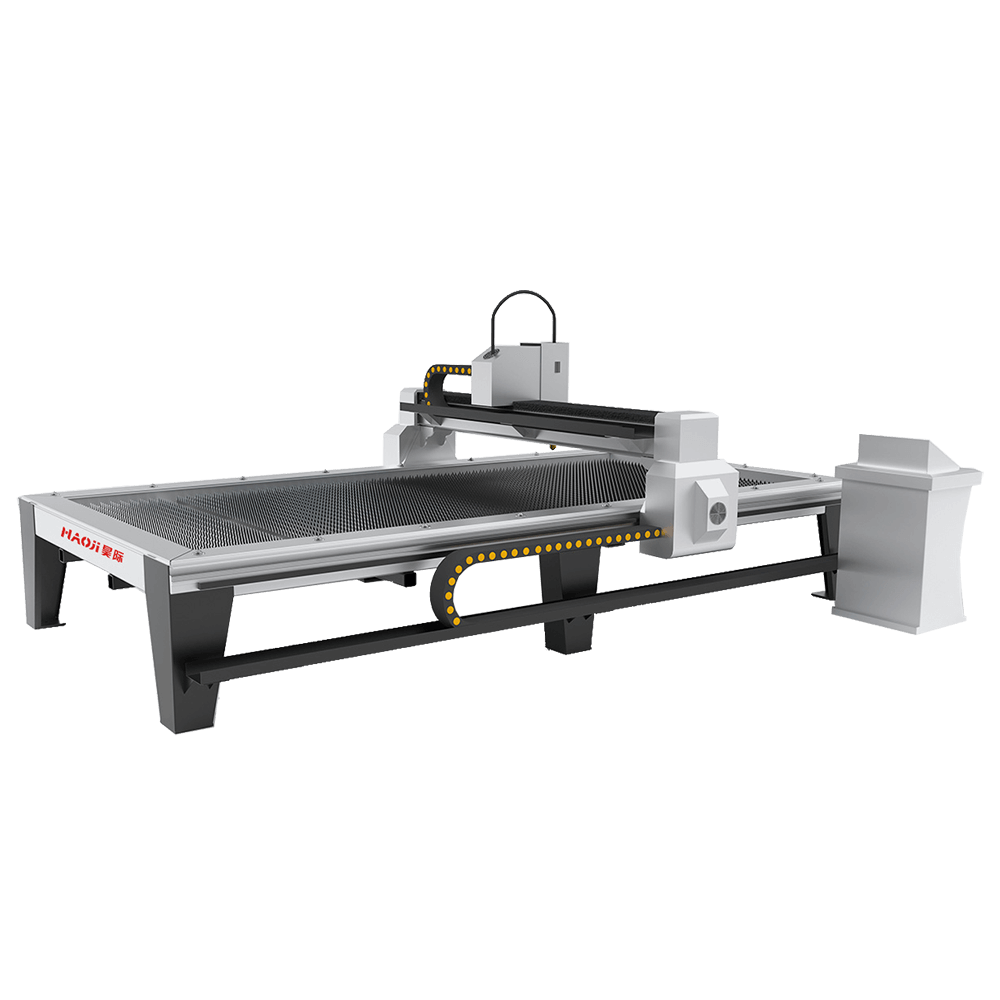

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

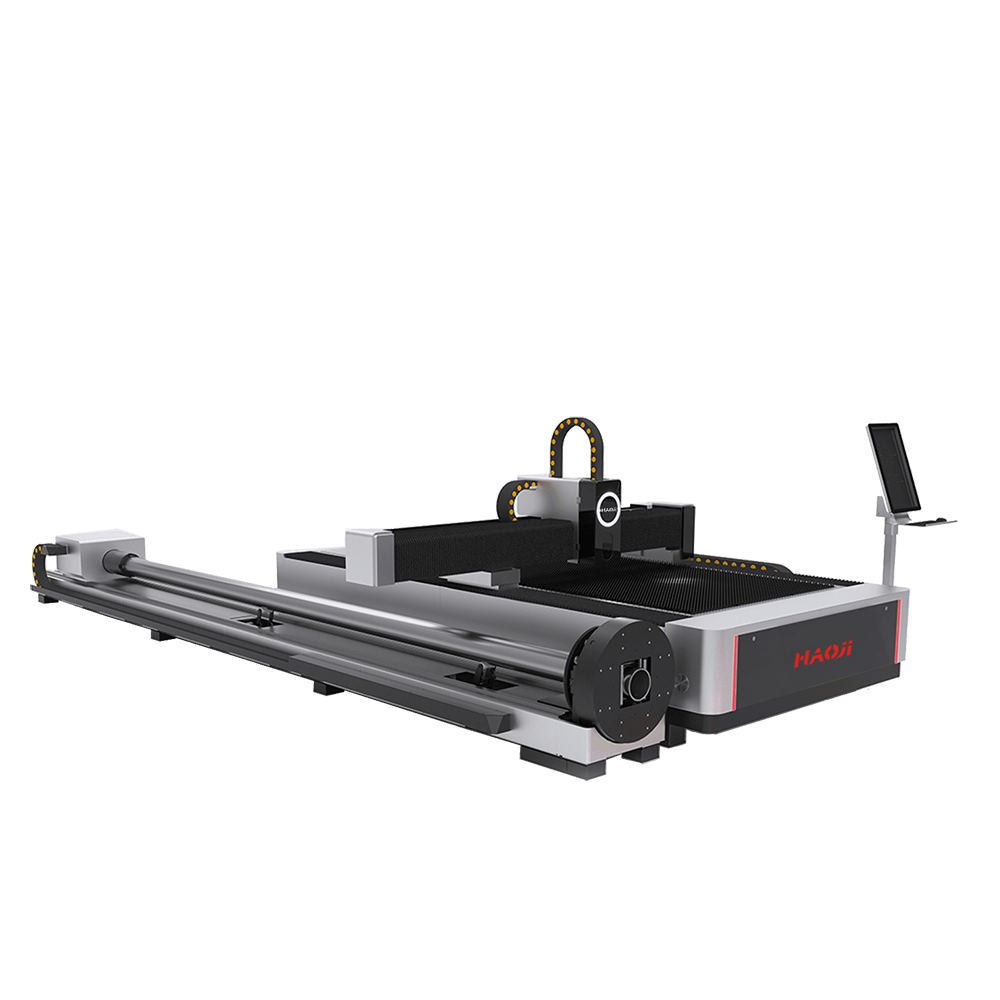

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

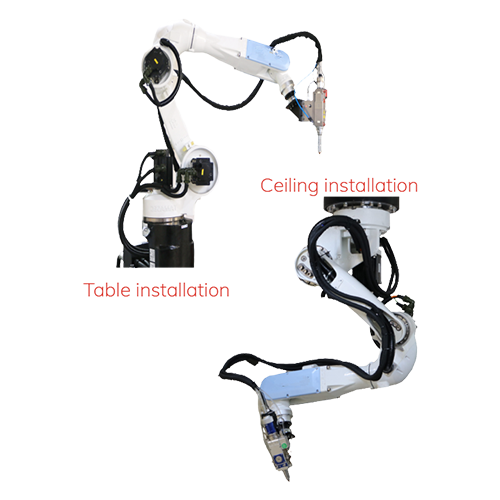

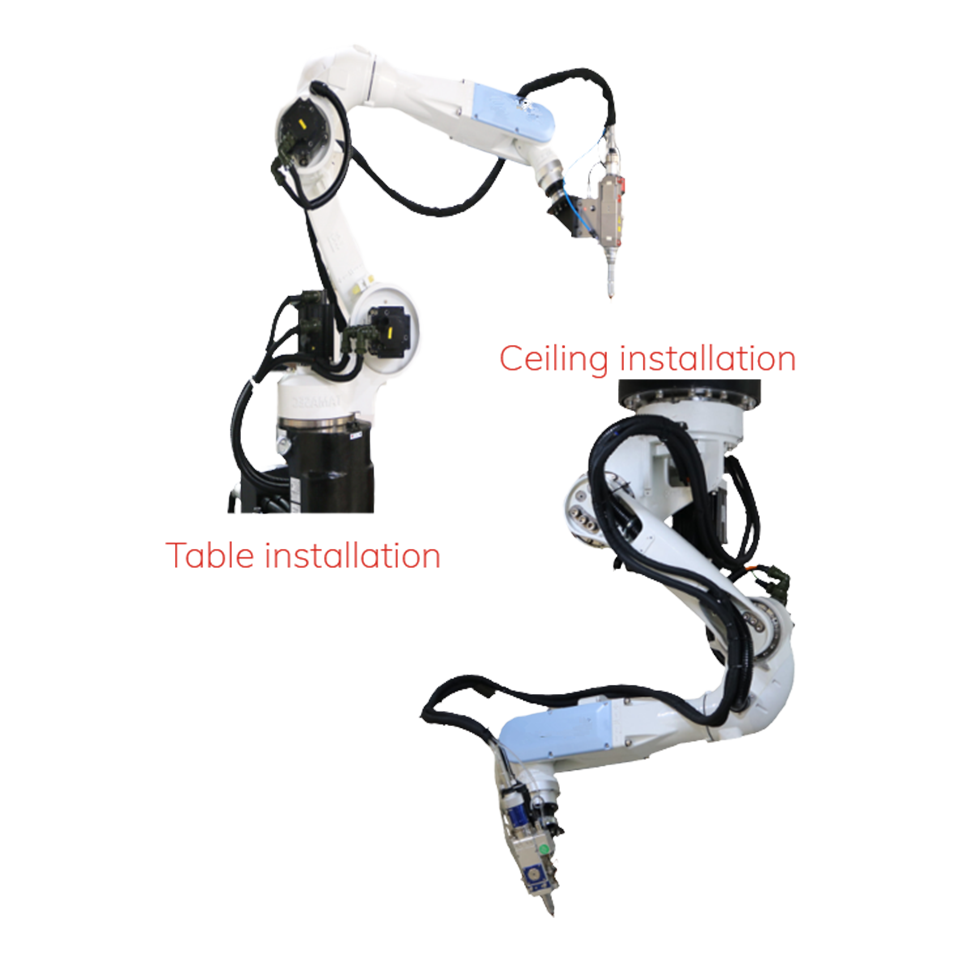

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

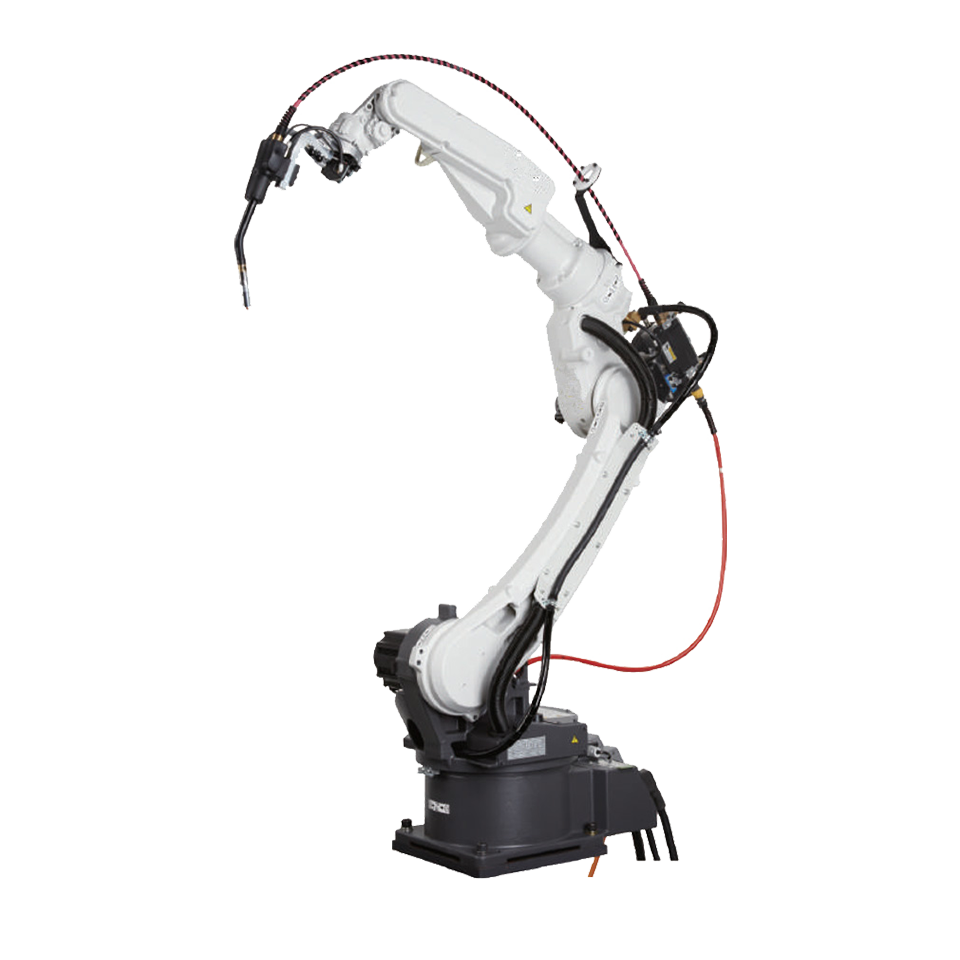

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:08-02 2021

Chiller clean and maintenance

1. Clean the filter every day to ensure good ventilation and heat dissipation.

2. The temperature of the chiller is generally kept at 22°C to 28°C (high temperature setting in summer is 28-32°C, low temperature setting is 25-29°C, please adjust in time in summer)

3. Change the water every 3 months (using steamed stuffing water), clean the water tank every time you change the water, circulate the dirty water in the equipment once with new steamed stuffing water, and then inject new water.

4. Replace the ordinary filter element of the water tank every 3 months, and replace the deionized filter element every 6 months to ensure that the filter element is clean.

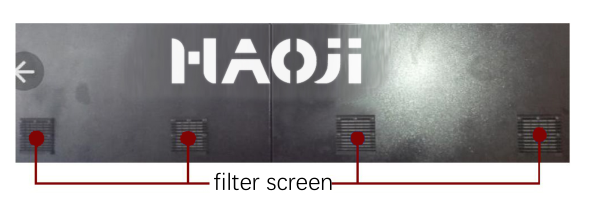

Electrical cabinet cleaning and maintenance

1.Remove the filter screen of the electric cabinet every month (it can be cleaned with water or compressed air) to ensure good ventilation and heat dissipation.

2. Dust is removed from the electrical cabinet every 3 months (once a month in a bad environment). Before dust removal, the equipment needs to be powered off (Note: Do not touch any terminal within 5 minutes after power off)

Use a vacuum cleaner or dry cloth (do not use compressed air to blow the dust directly) to clean the dust in the electric cabinet

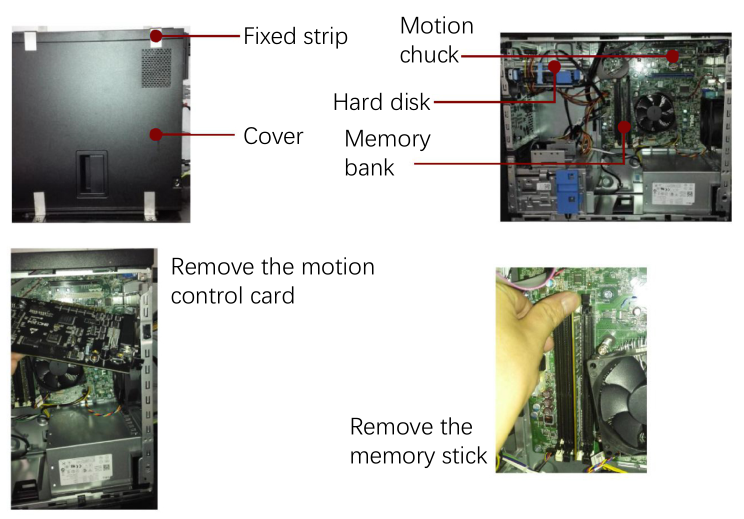

3. Every half a year (every 3 months in bad environment), you need to clean the industrial computer, remove the fixing strip, and remove the cover. The motion control card and memory bar can be removed and cleaned. Please use a clean dry cloth to clean.

Recommend similar maintenance guide for you:Cleaning and maintenance of machine tool transmission part