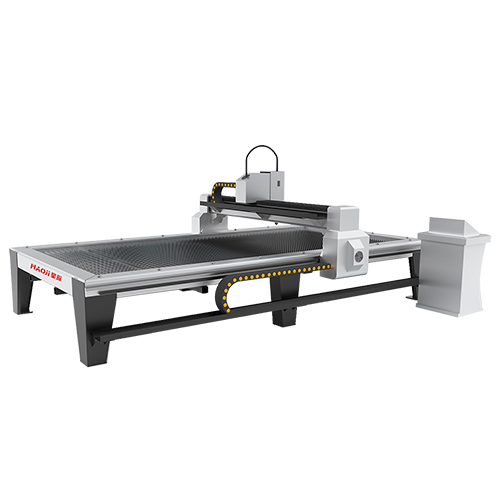

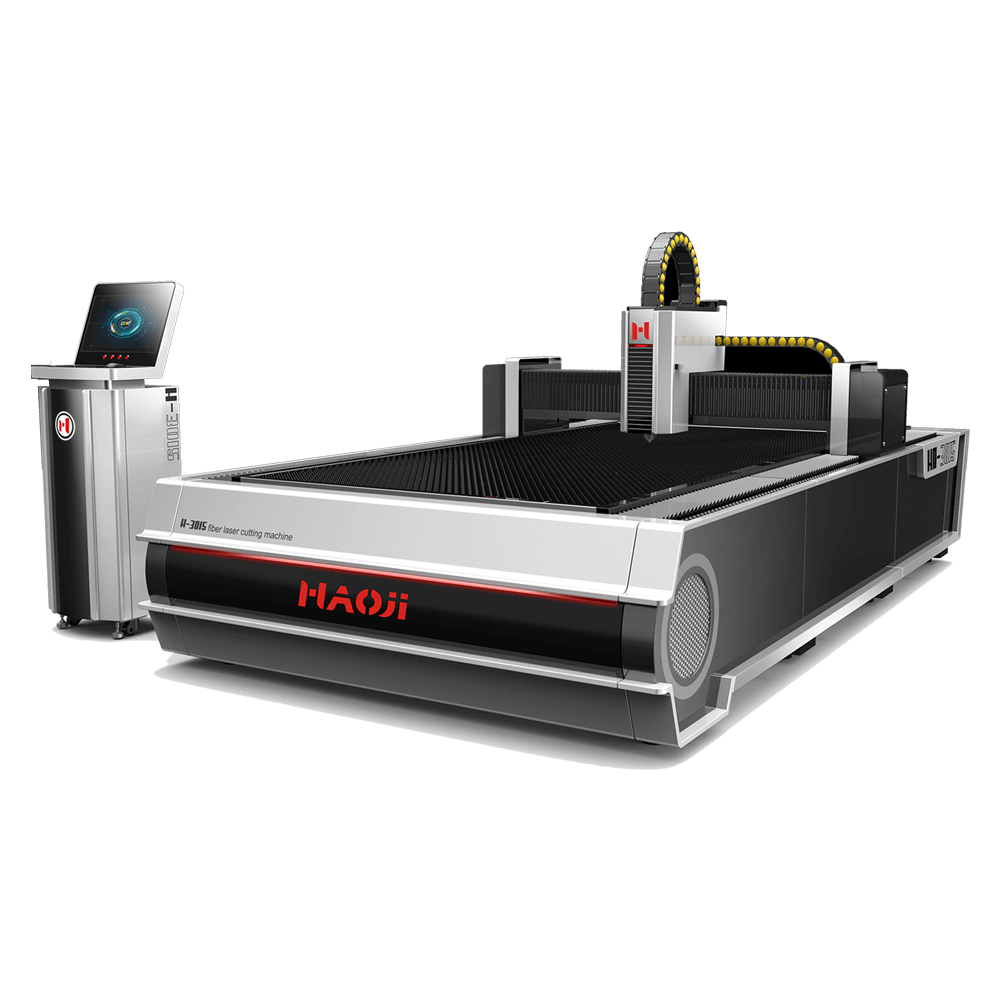

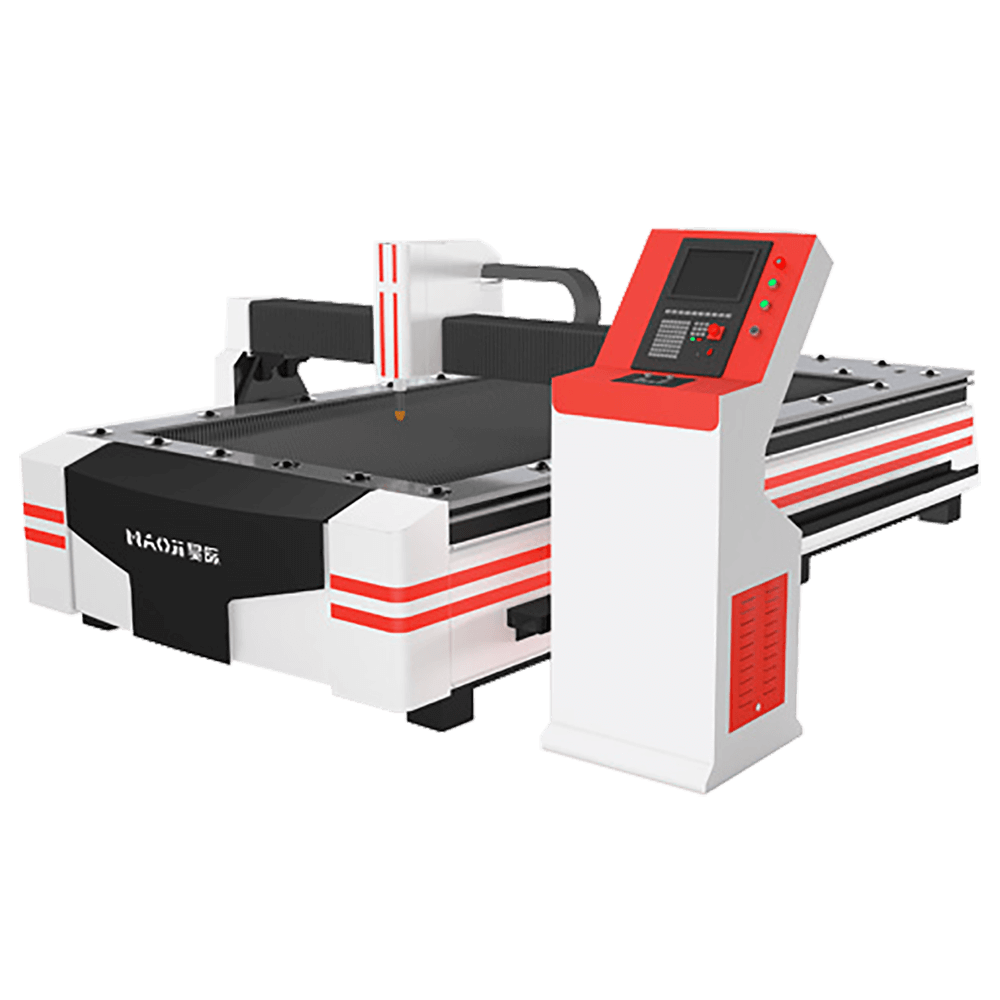

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

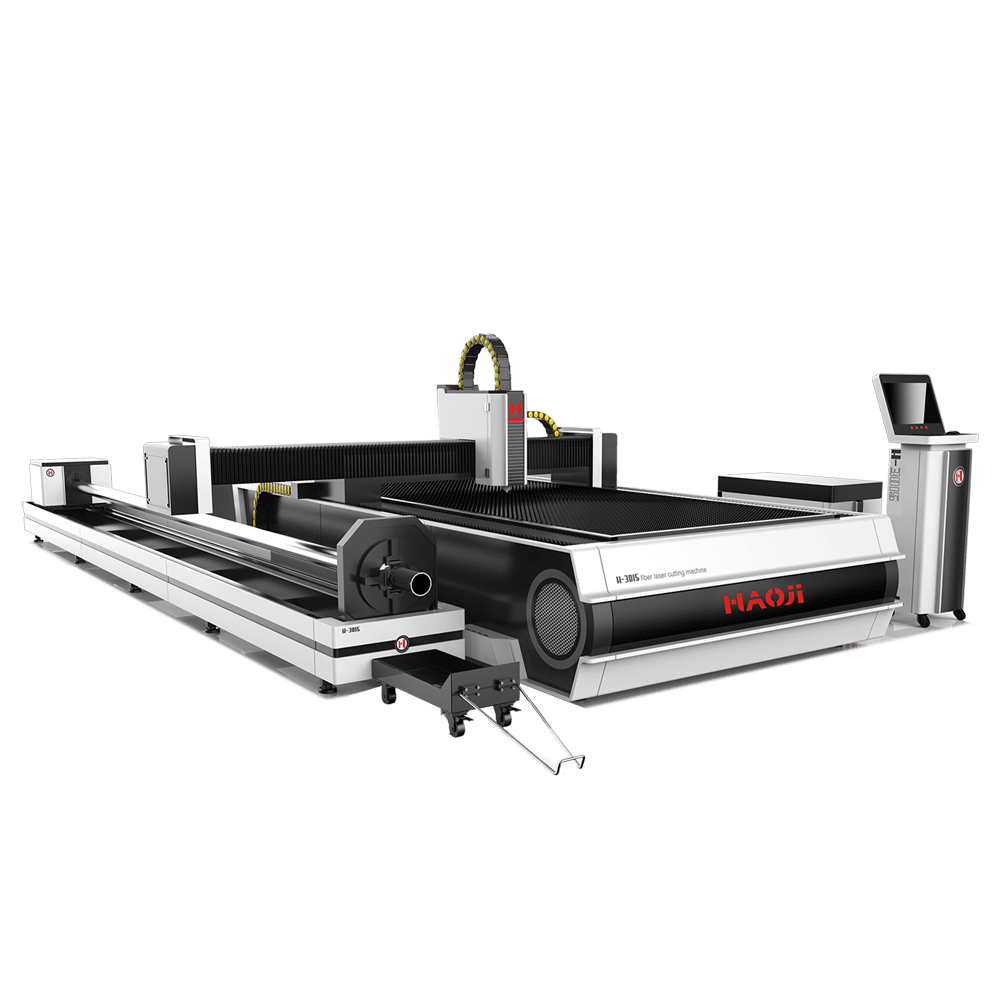

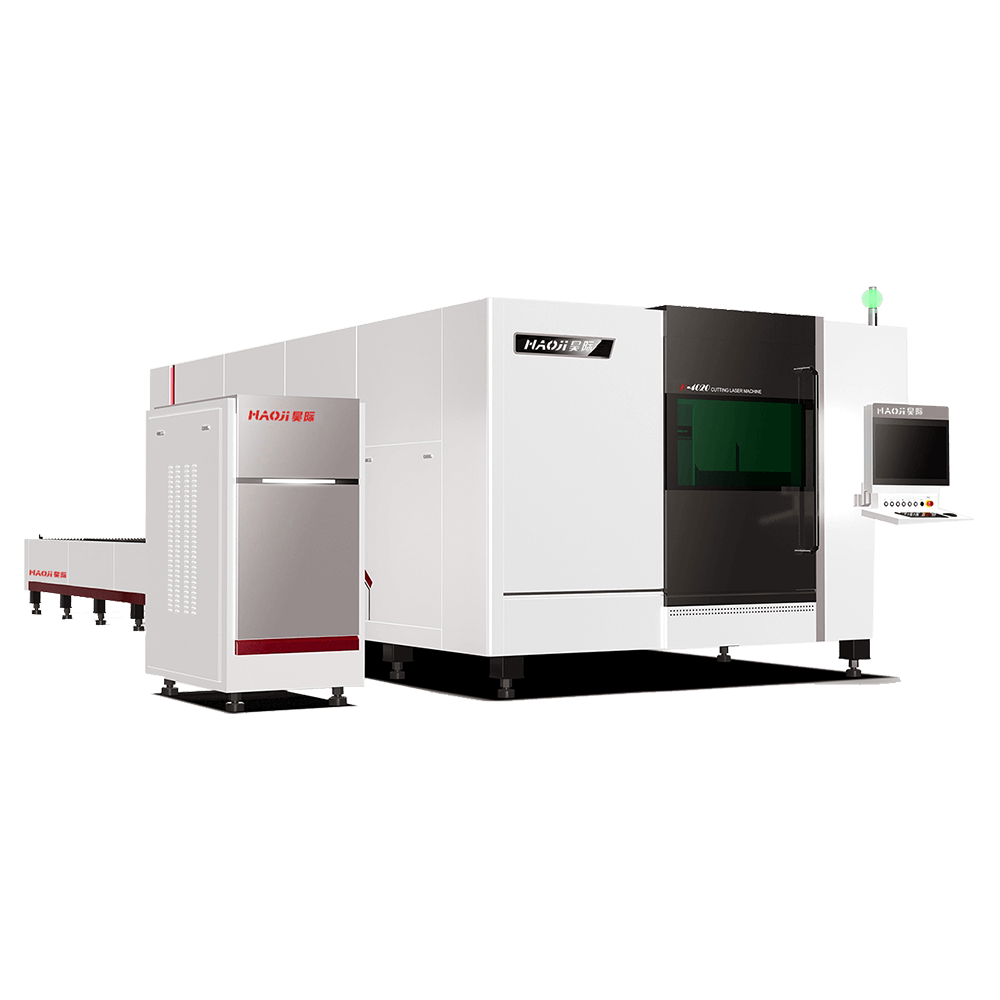

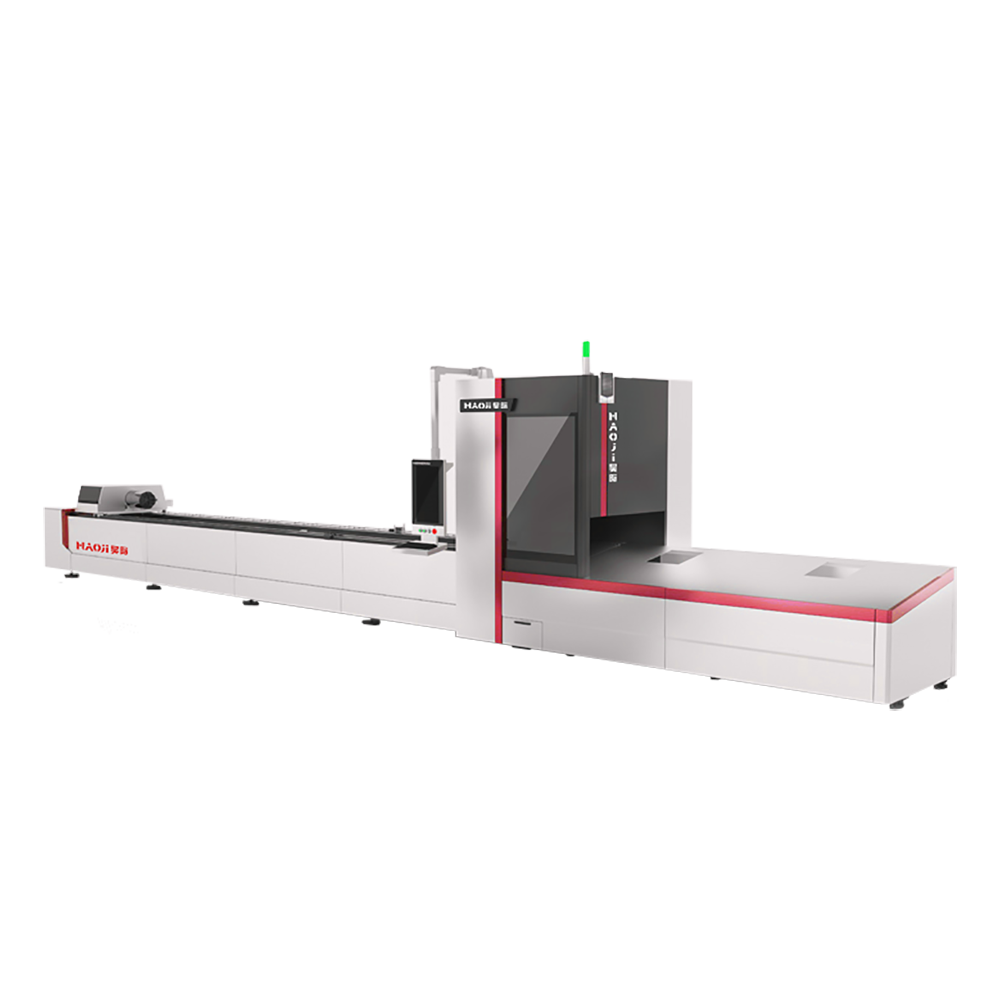

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

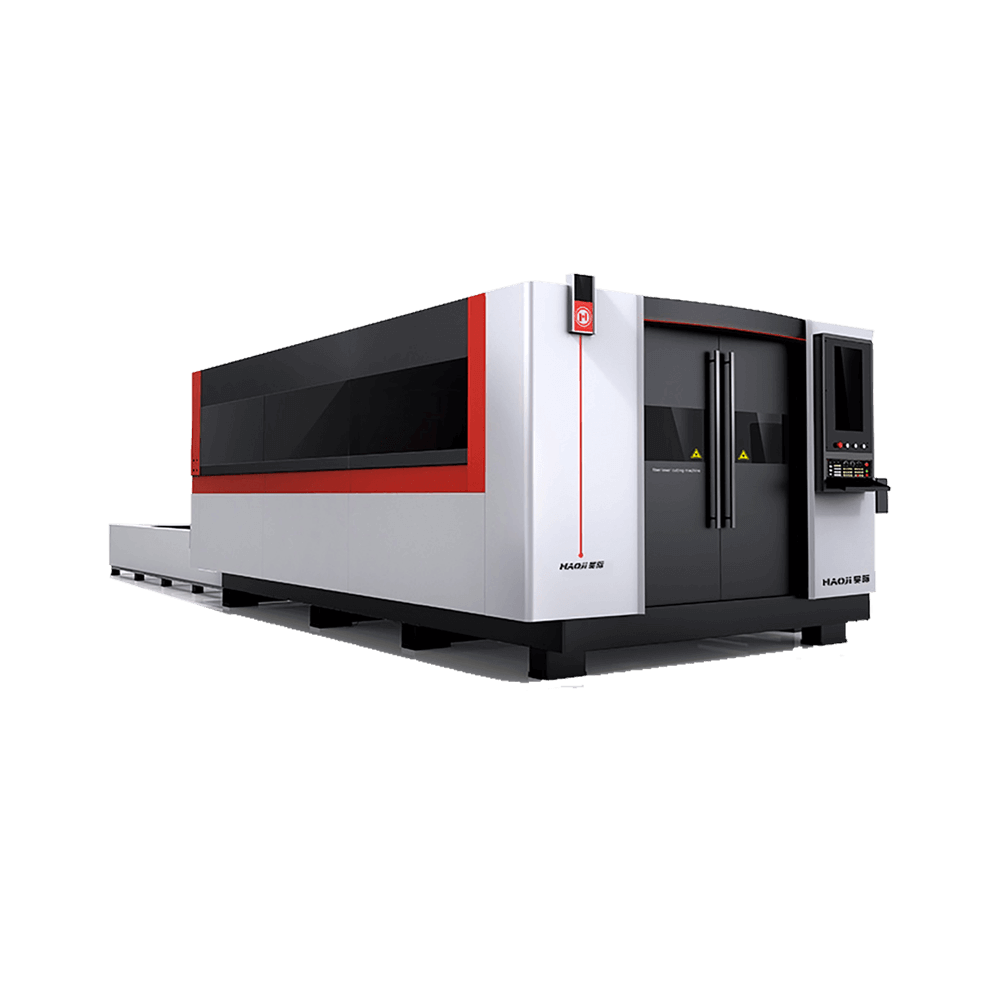

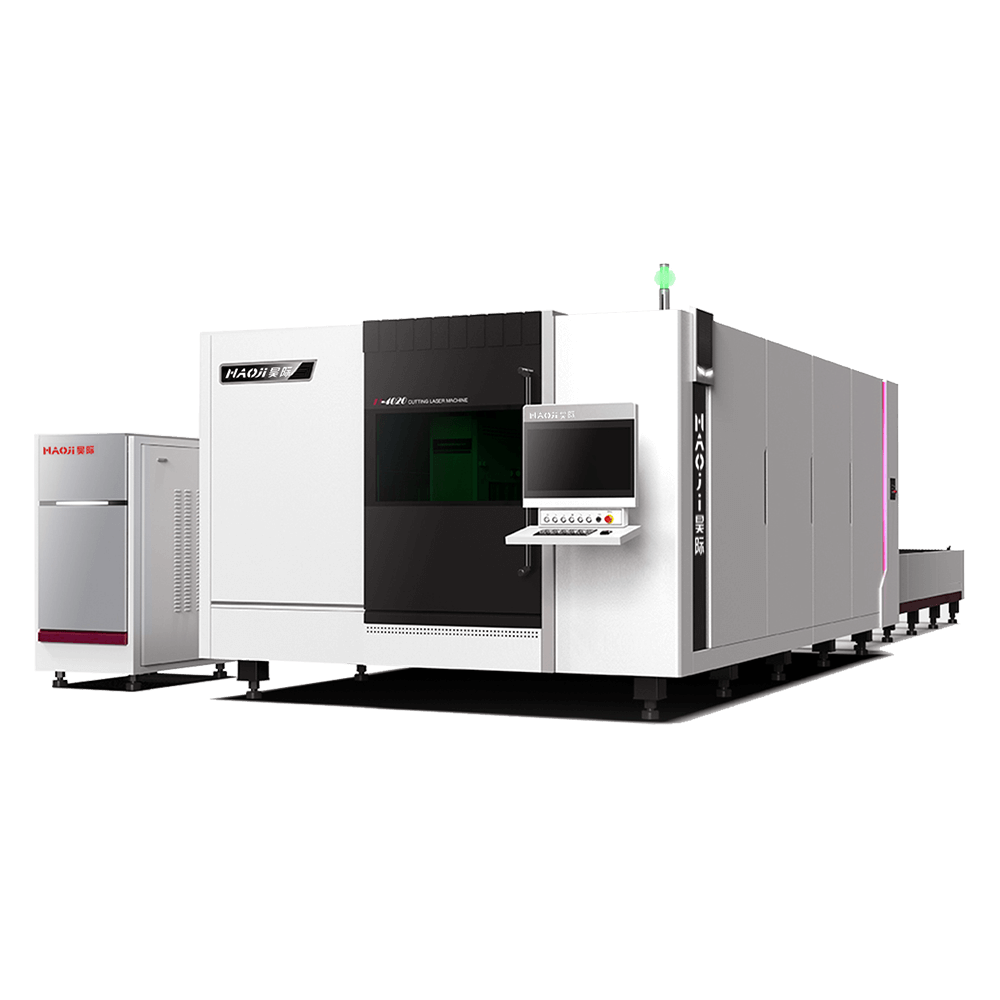

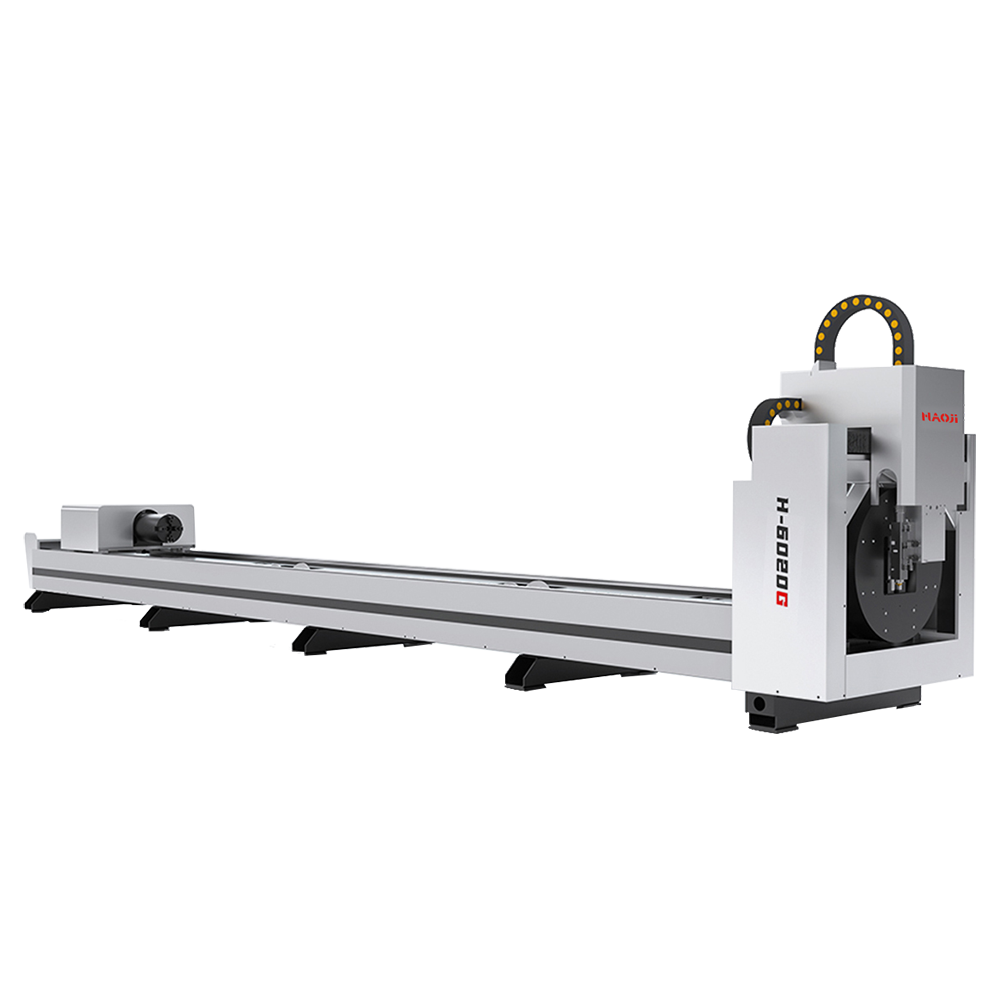

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

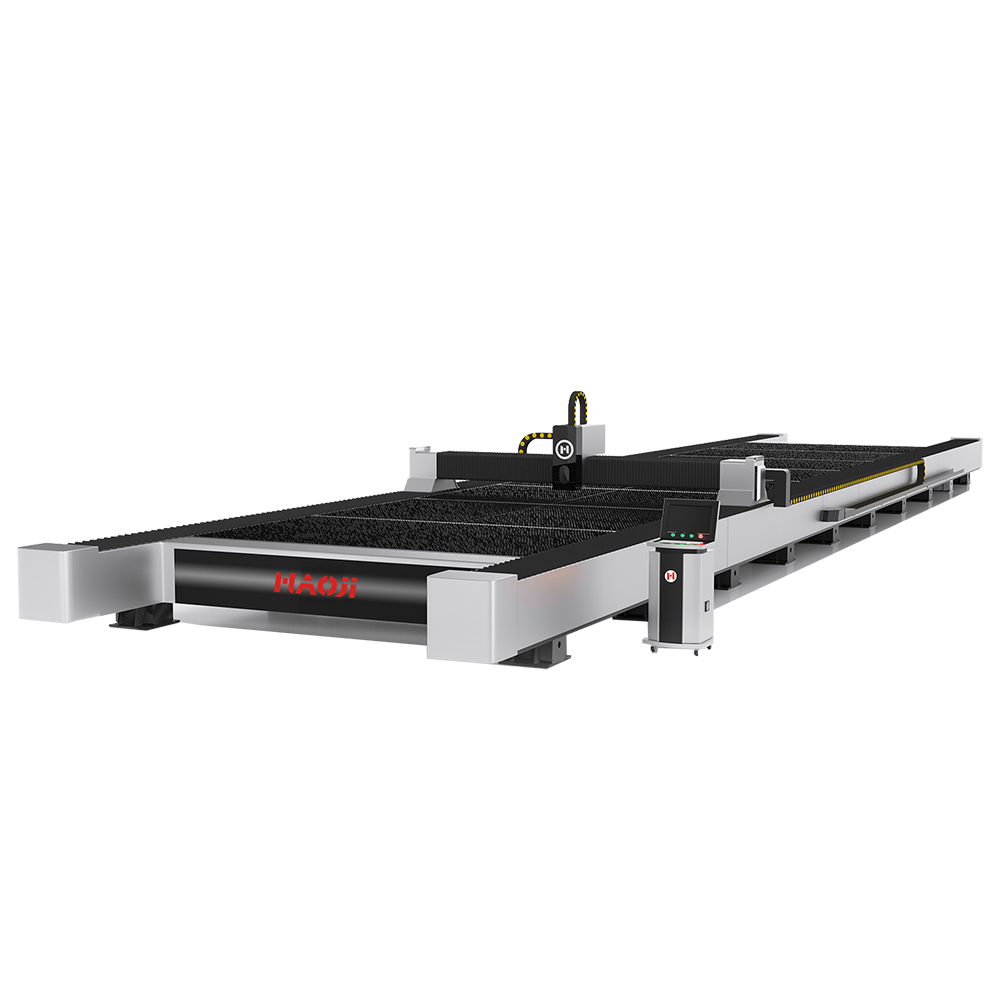

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

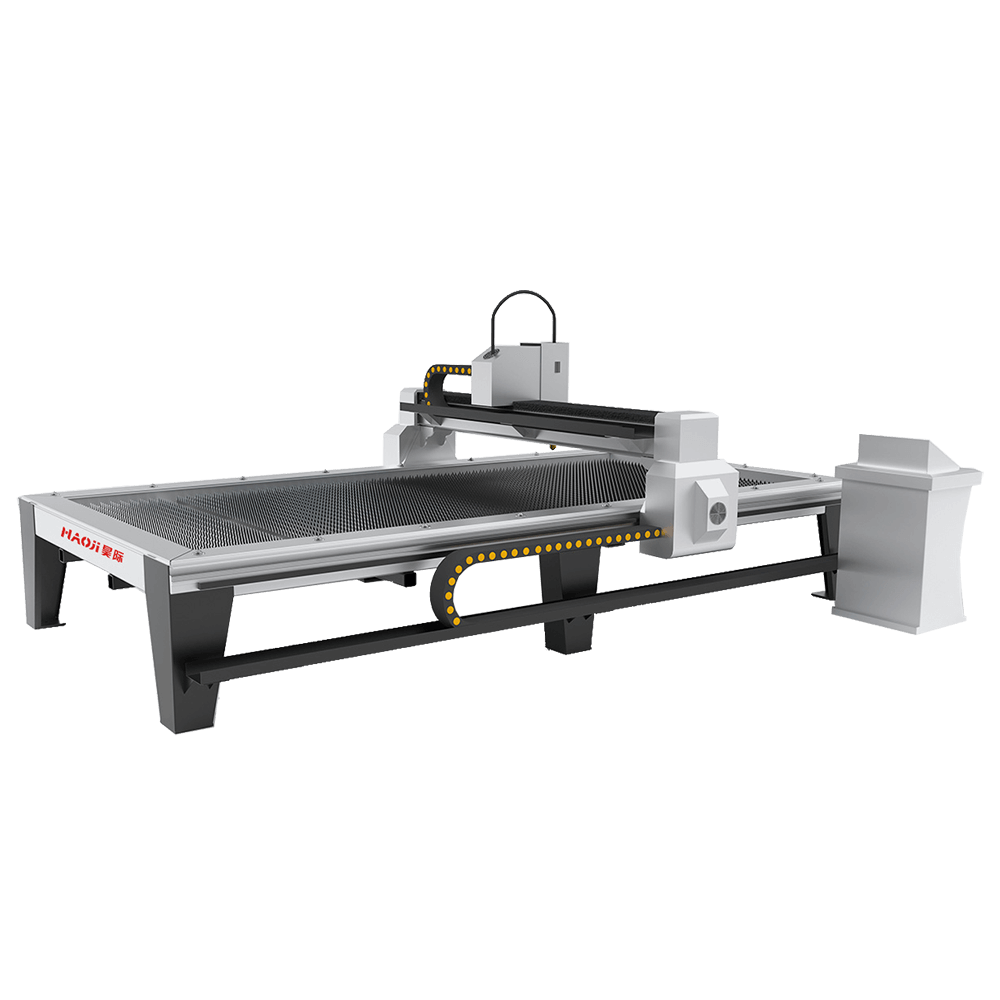

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

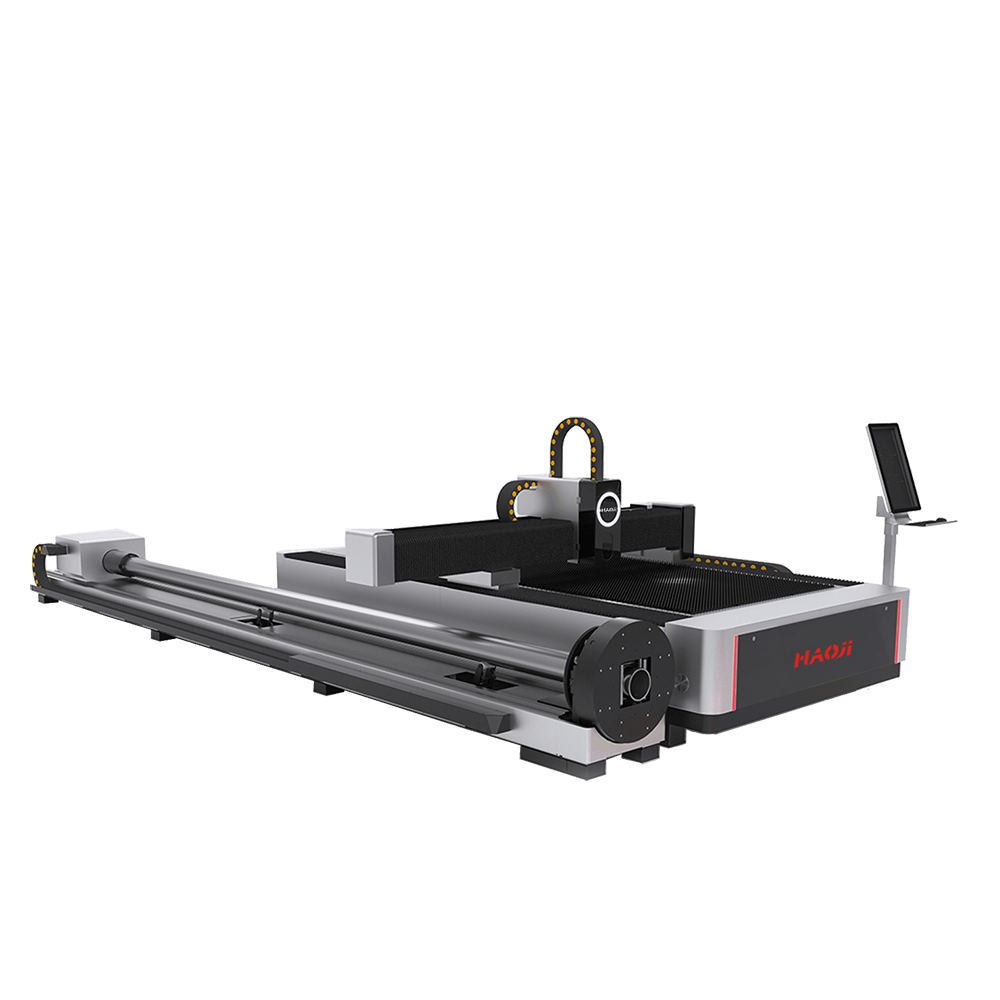

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

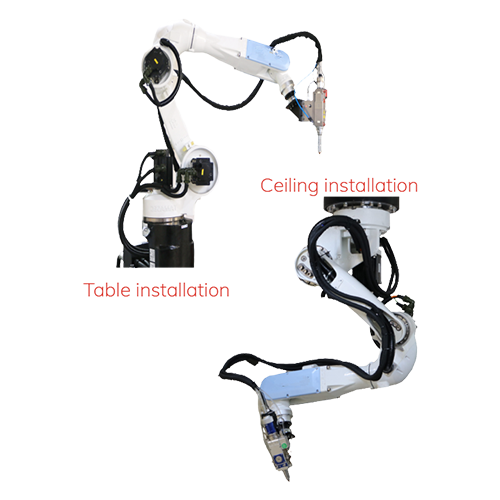

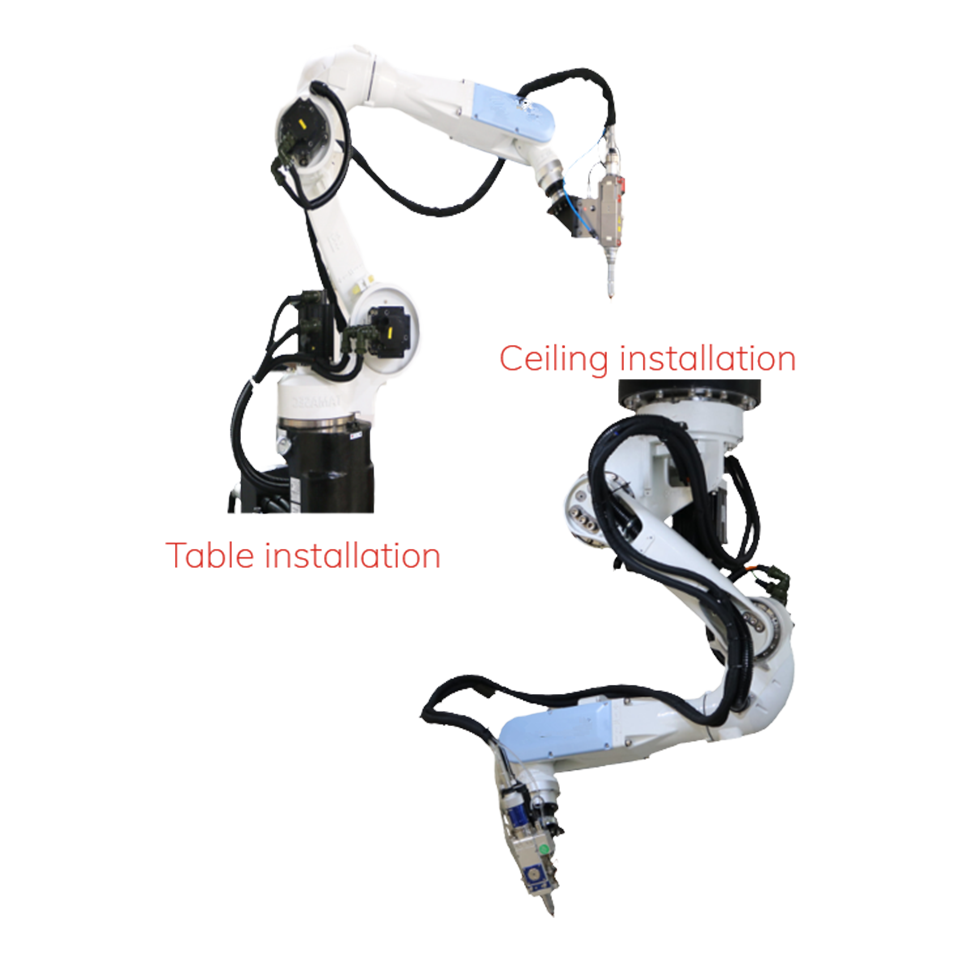

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

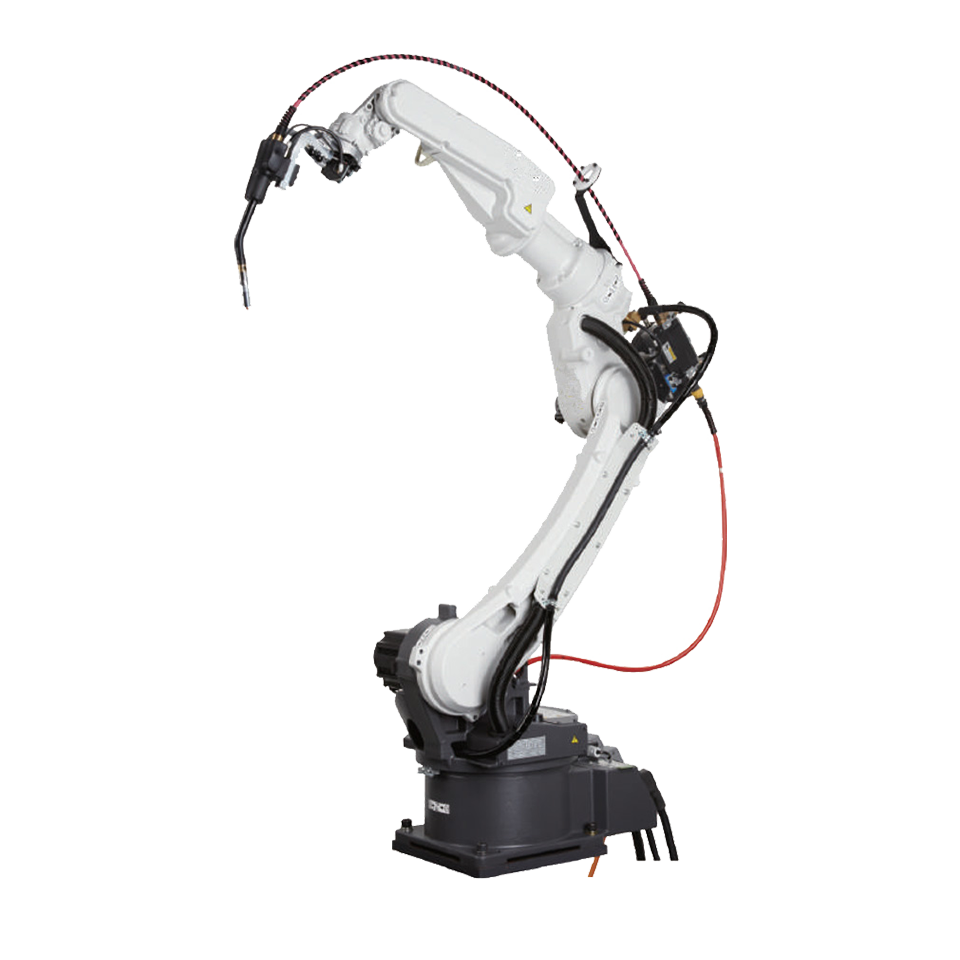

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:07-03 2021

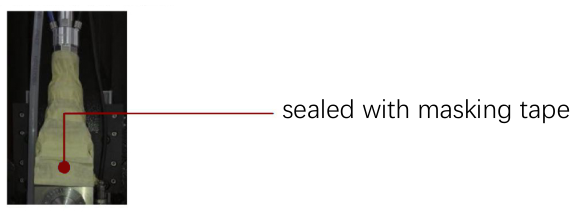

It is necessary to maintain the machine after it has been used for a period of time for laser cutting machine user. How much do you know about maintenance? Here are 5 tips to cut head clean and maintenance of laser cutting machine, hope it can help you learn more.

1.In order to ensure that no dust enters the cutting head, the upper part of the cutting head can be sealed with asking tape after the equipment is installed and debugged.

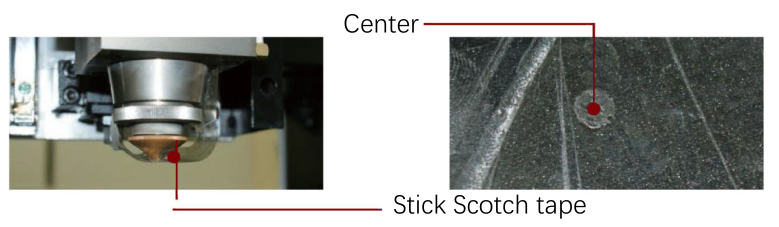

2. Check whether the light comes out from the center of the nozzle before cutting every day, otherwise, please re-dimming and calibrate

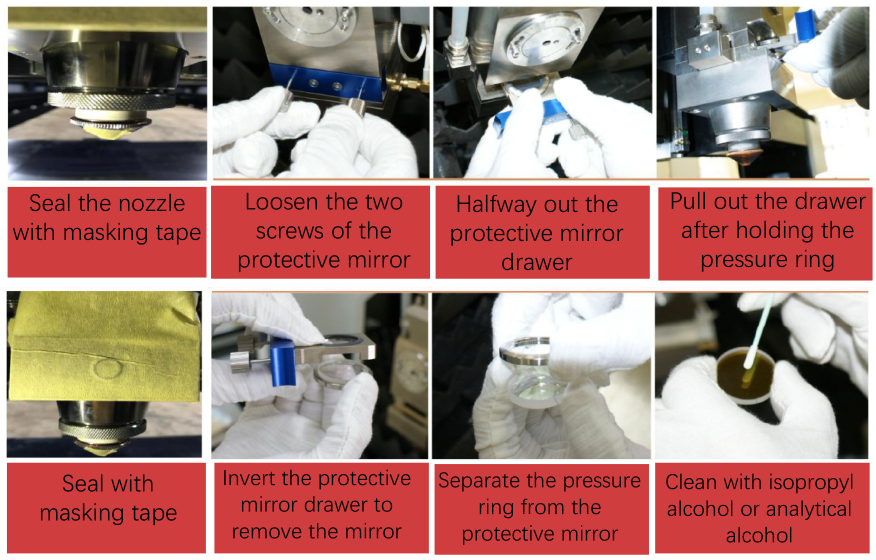

3. Check whether the protective mirror is clean every day before cutting, otherwise, please clean the protective lens with isopropanol or analytical pure alcohol (purity above 99.5%), clean and clean without leaving water marks. Attentions:

(1)Turn off the surrounding fans before removing the protective mirror drawer; seal the nozzle opening with masking paper

(2) After pulling out the protective mirror drawer, immediately seal the protective mirror drawer exit with masking paper.

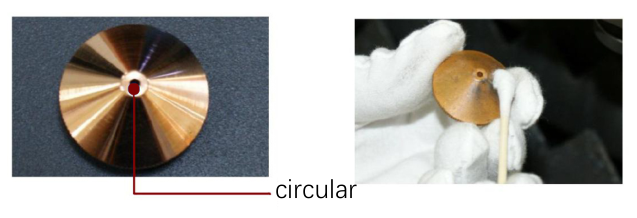

4. Check the roundness and cleanliness of the nozzle before each cut and clean the nozzle.

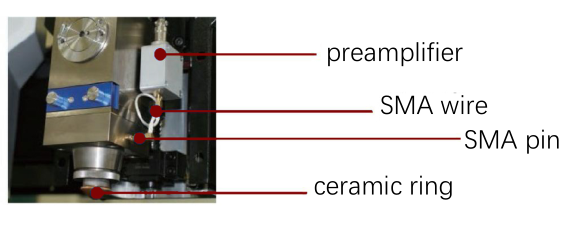

5. Check whether the ceramic ring, SMA wire, SMA pin, preamplifier is loose or have foreign body in it and please tighten and clean every day.

Recommend similar maintenance (Fiber laser generator maintenance in Summer) for you.

For more details of laser cutting machine maintenance, welcome to follow Haoji Technology.