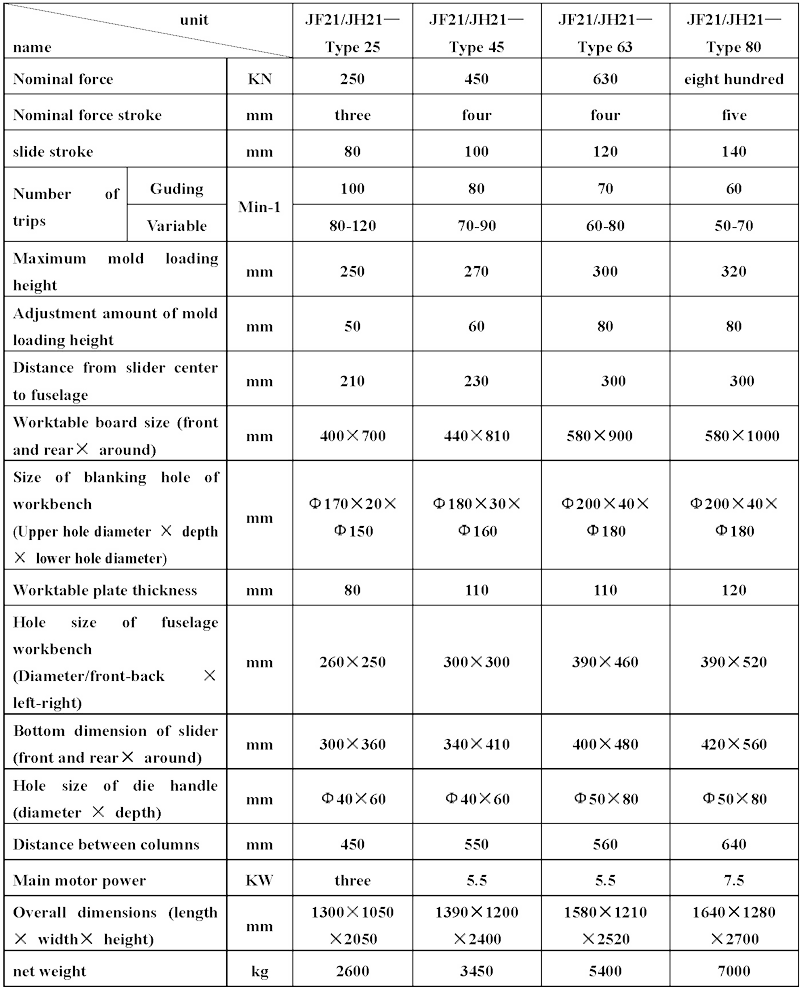

Description

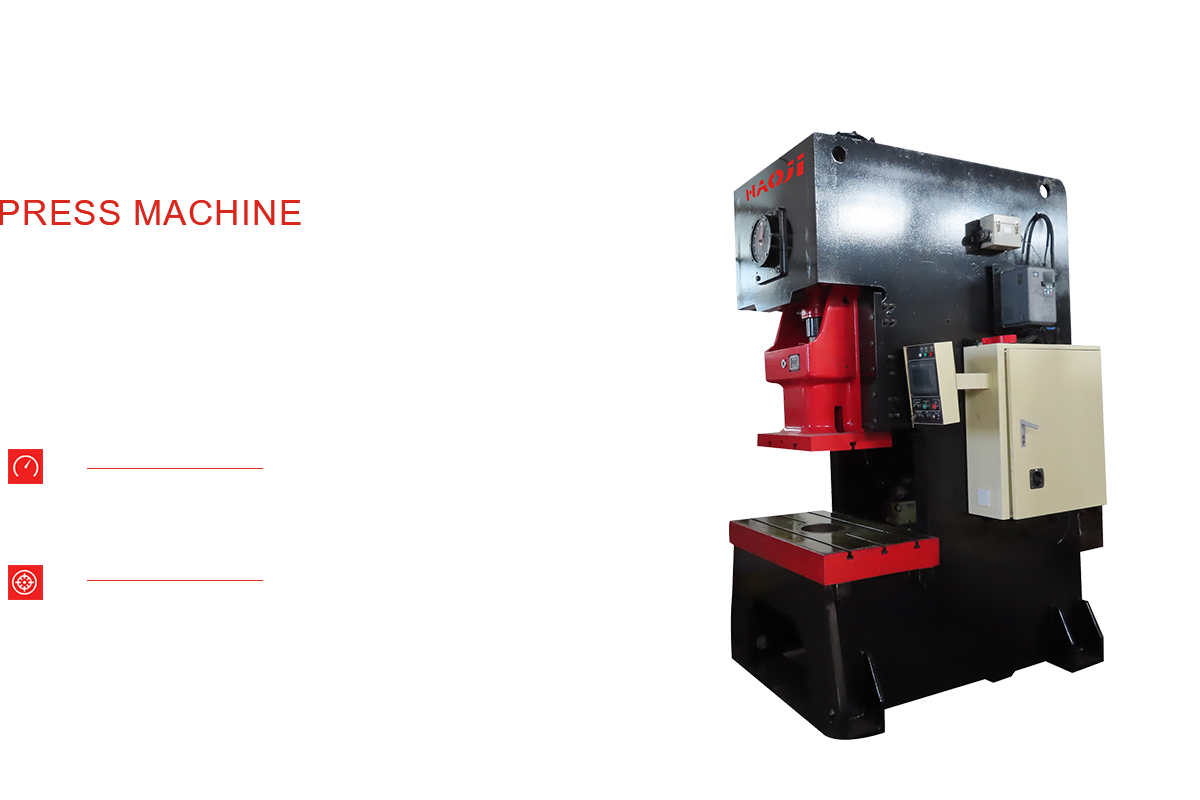

The press consists of machine body, transmission system, clutch, slider, balancer, transmitter, air pipeline, lubrication system and electrical system.

☆ The fuselage is welded by high-quality steel plate, and the internal stress is eliminated after aging treatment, with good strength and small deformation.

Good accuracy and stability.

☆ The crankshaft is placed longitudinally, and the fulcrum distance is small, which ensures the better rigidity and disturbance of the crankshaft.

☆ Clutch: Shanghai Yiyu dry clutch (JH21-80 to JH21-315) produced by Shanghai Yiyu using Japanese technology. Its main components, such as friction plates, springs, seals and bearings, are imported. The processing and assembly requirements are completely in accordance with Japanese technical requirements, with stable quality and longer service life, which is several times higher than other domestic clutches.

☆ The slider is made of resin sand, with good internal organization and beautiful appearance; The rectangular guide rail is adopted, and the surface of the guide rail is inlaid with copper plate, which has good accuracy retention. The hydraulic pad in the slider effectively controls the machine tool to run within the nominal force range through the hydraulic overload protection device imported from Japan, and protects the machine tool parts from damage.

☆ The mold loading height is adjusted electrically (except for JH21-25 and JH21-45, which are manually adjusted), and the mold loading height is adjusted by a mechanical digital indicator with the accuracy of 0.1mm, which is convenient to adjust.

☆ Equipped with pneumatic balancer to balance the weight of slider and upper die, the machine tool runs more stably.

☆ The electric control part adopts French Schneider button, Siemens AC contactor and thermal relay. JH21-125 adopts the combination of cam controller (Omron spring leaf) and encoder (Italy) to control the transmission, which makes the machine tool stop safer and more reliable. Panasonic PLC and man-machine interface (touch screen) are used for centralized control, which has the functions of crankshaft rotation angle display and fault prompt, making maintenance more convenient and time-saving.

☆ Above JH21-125, electric oil pump is used for centralized lubrication, and quantitative oil separator with circulation indication function is installed, which makes lubrication more convenient and reliable.

☆Adopt the safety double valve of Japanese Fengxing company or TACO, and the machine tool moves safely and reliably.