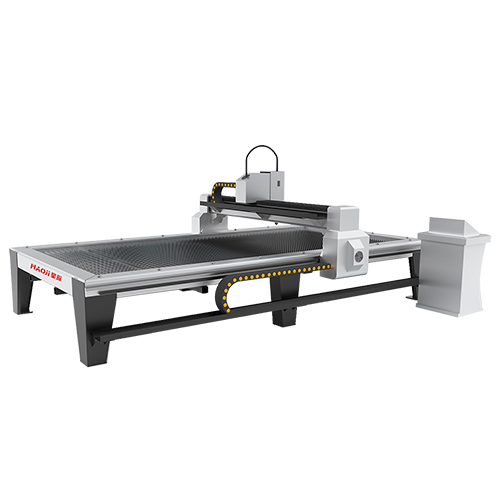

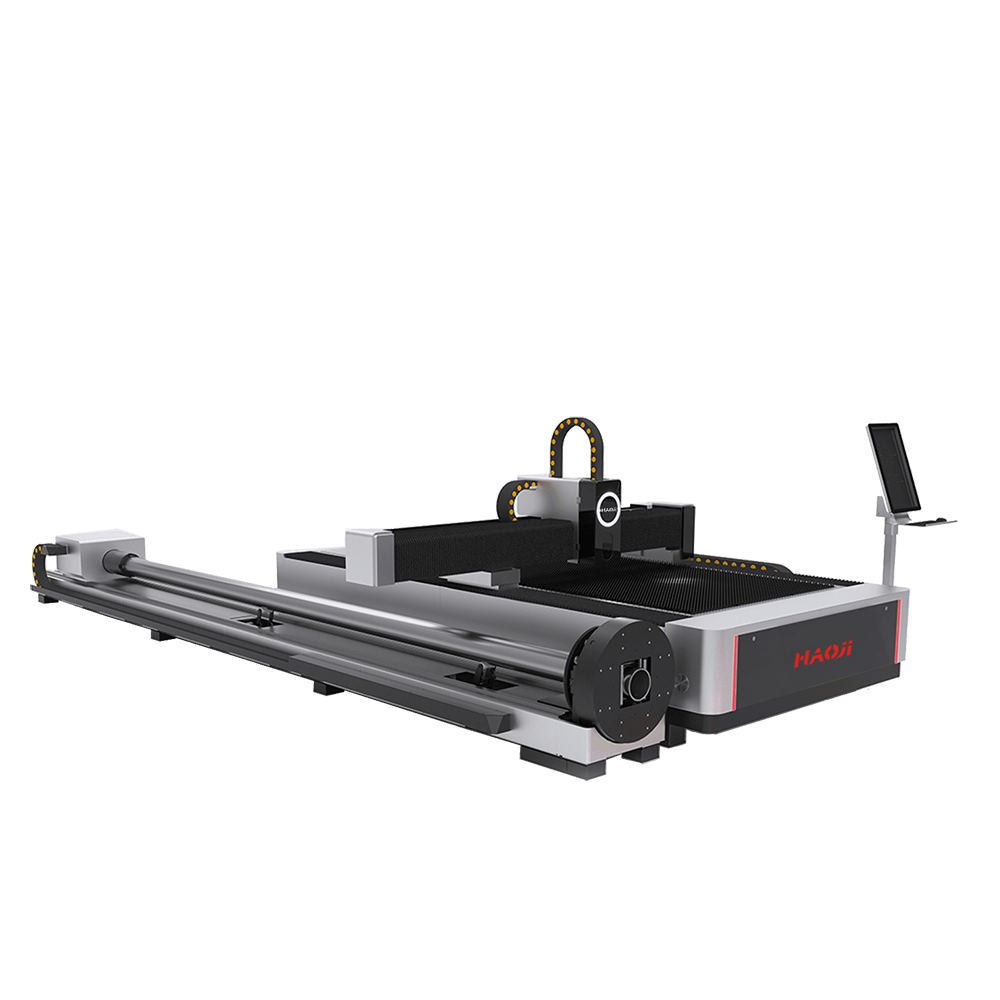

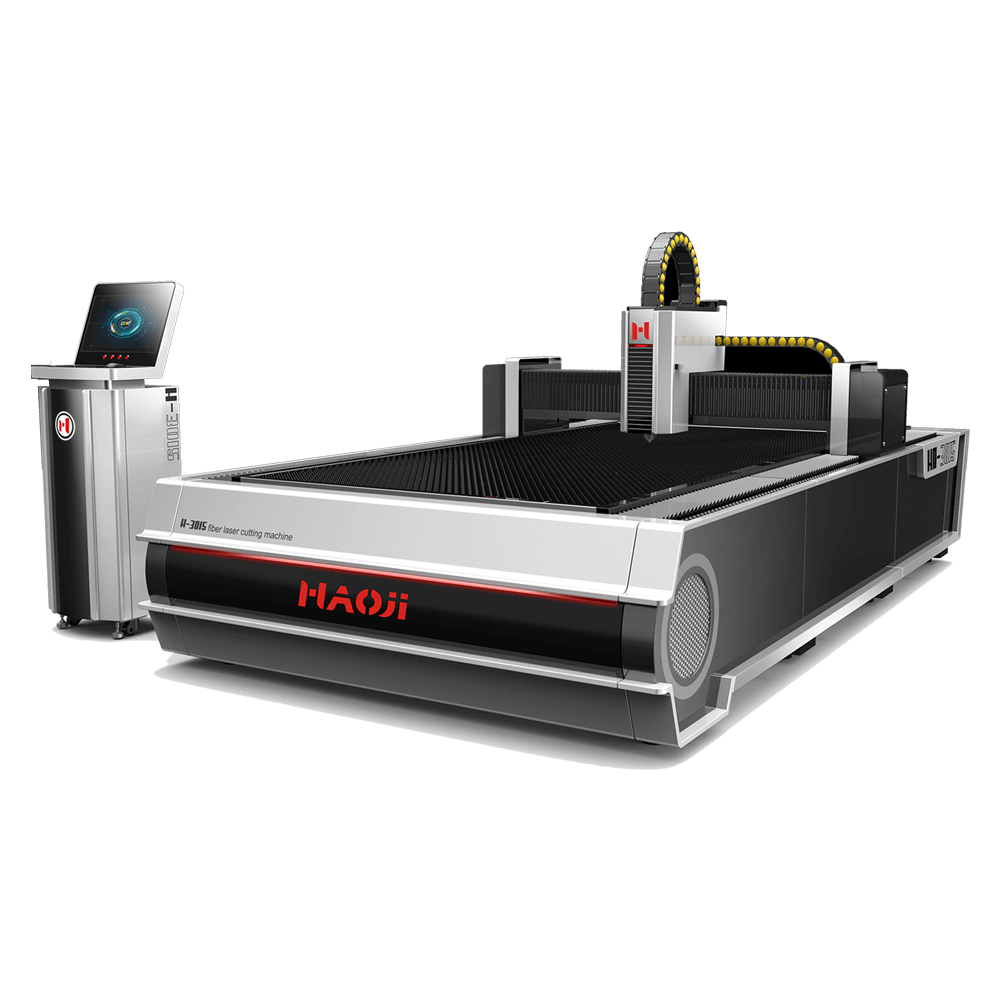

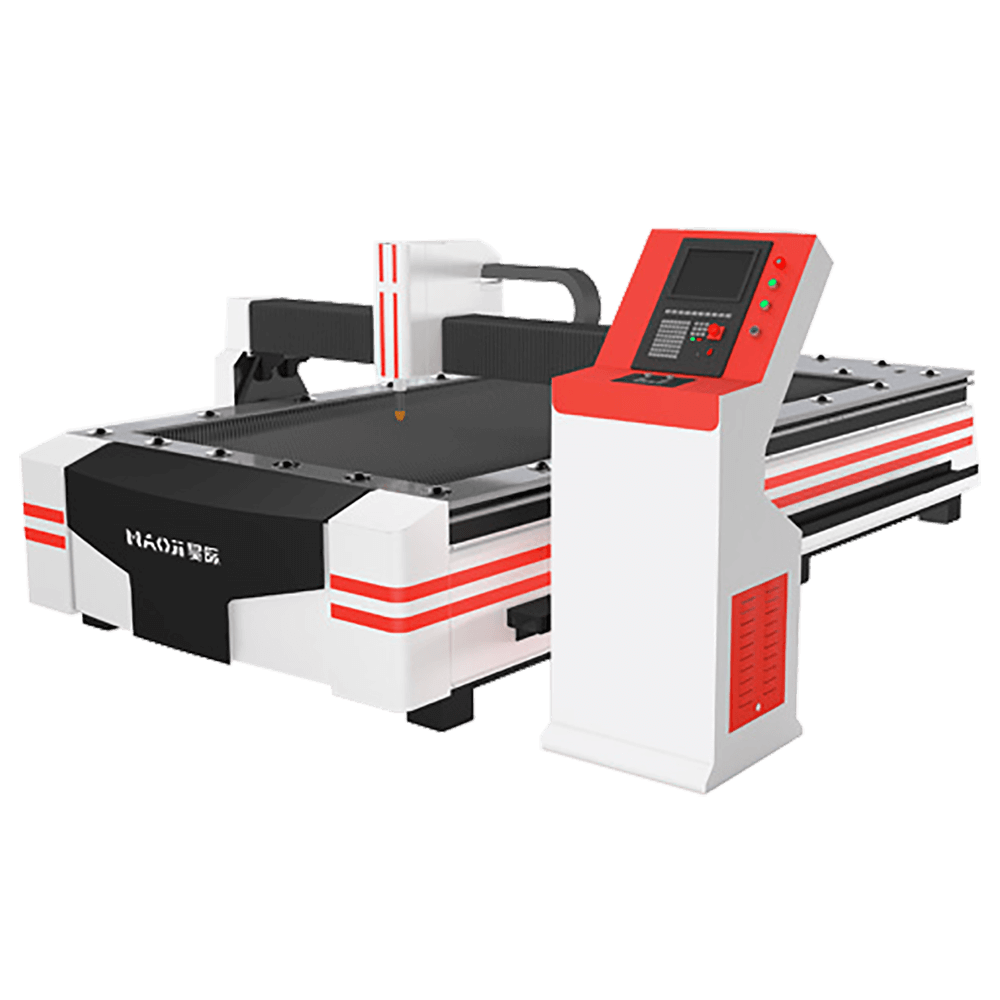

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

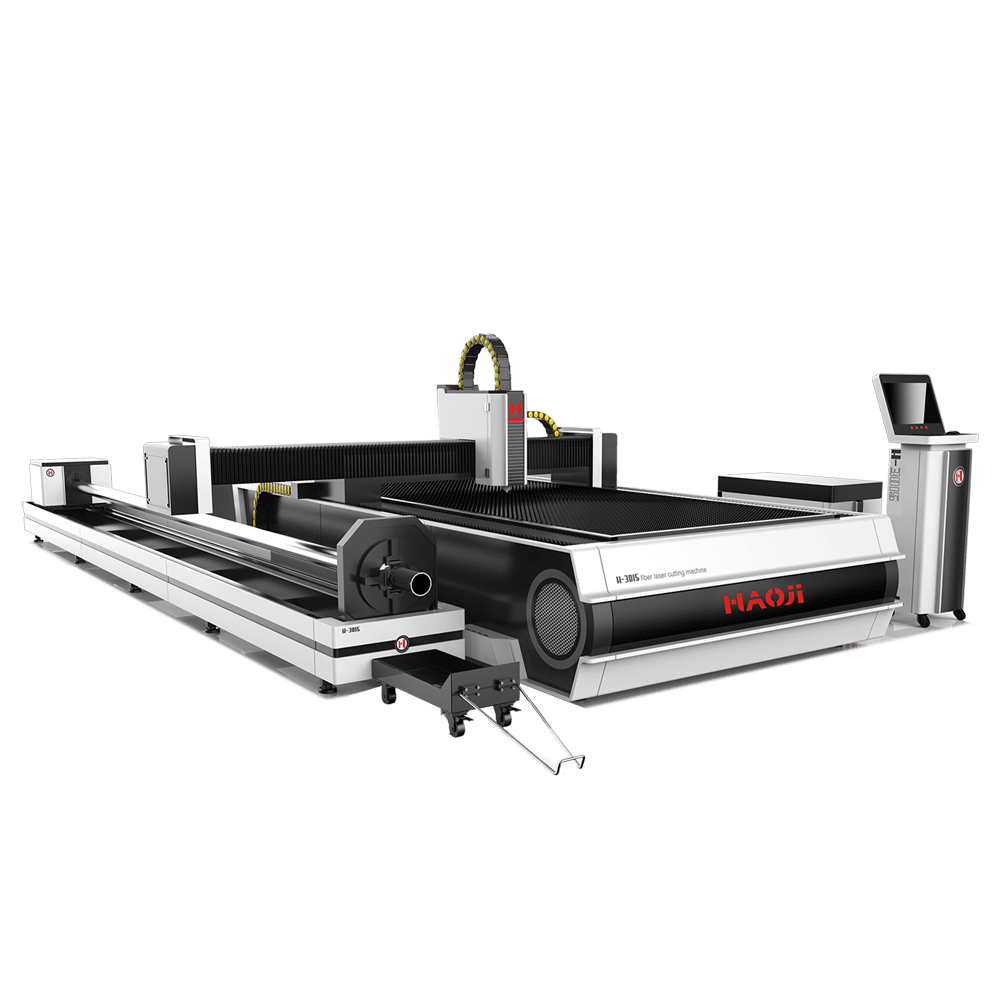

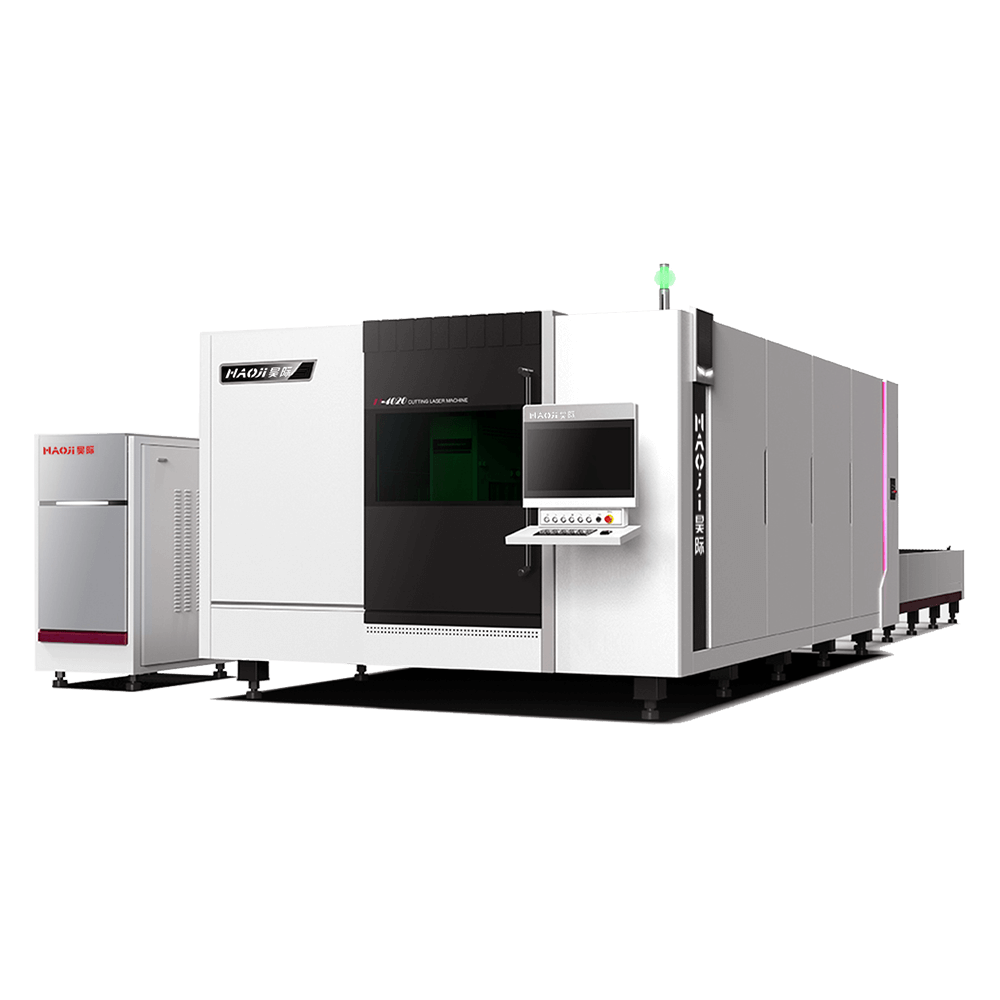

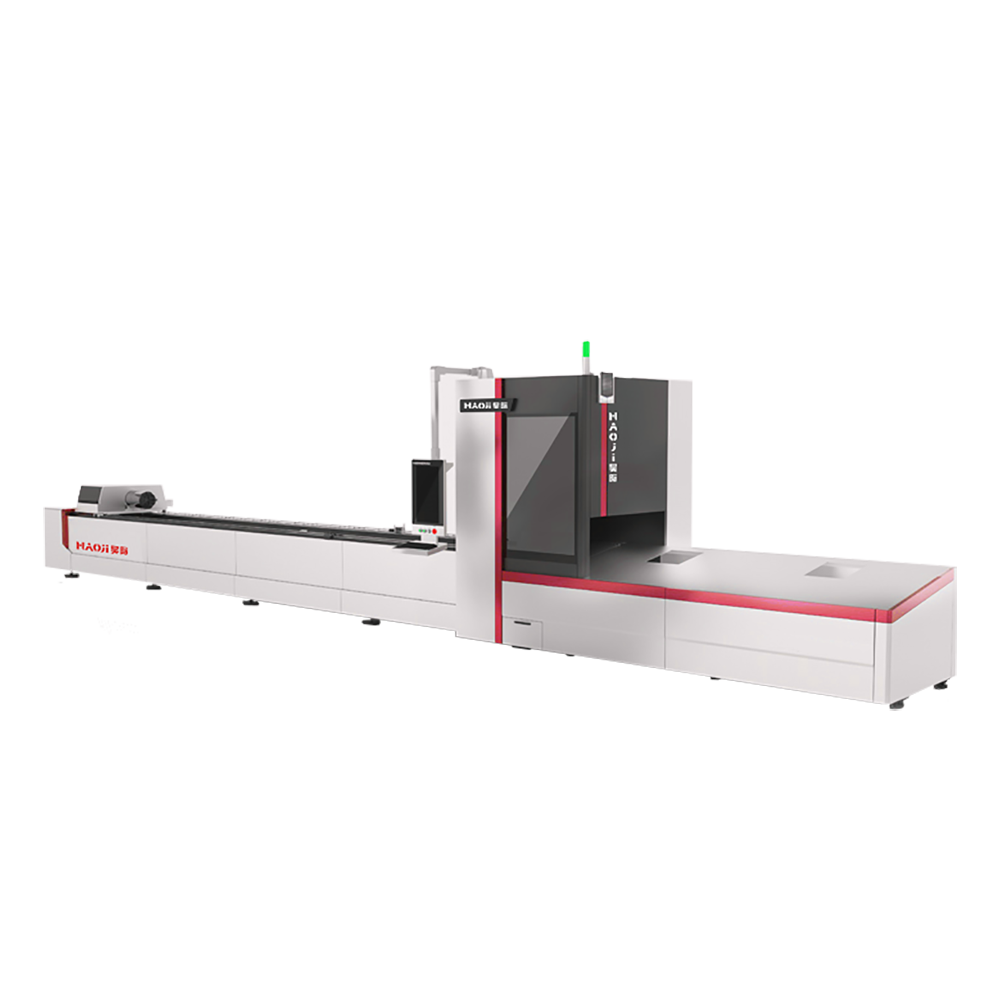

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

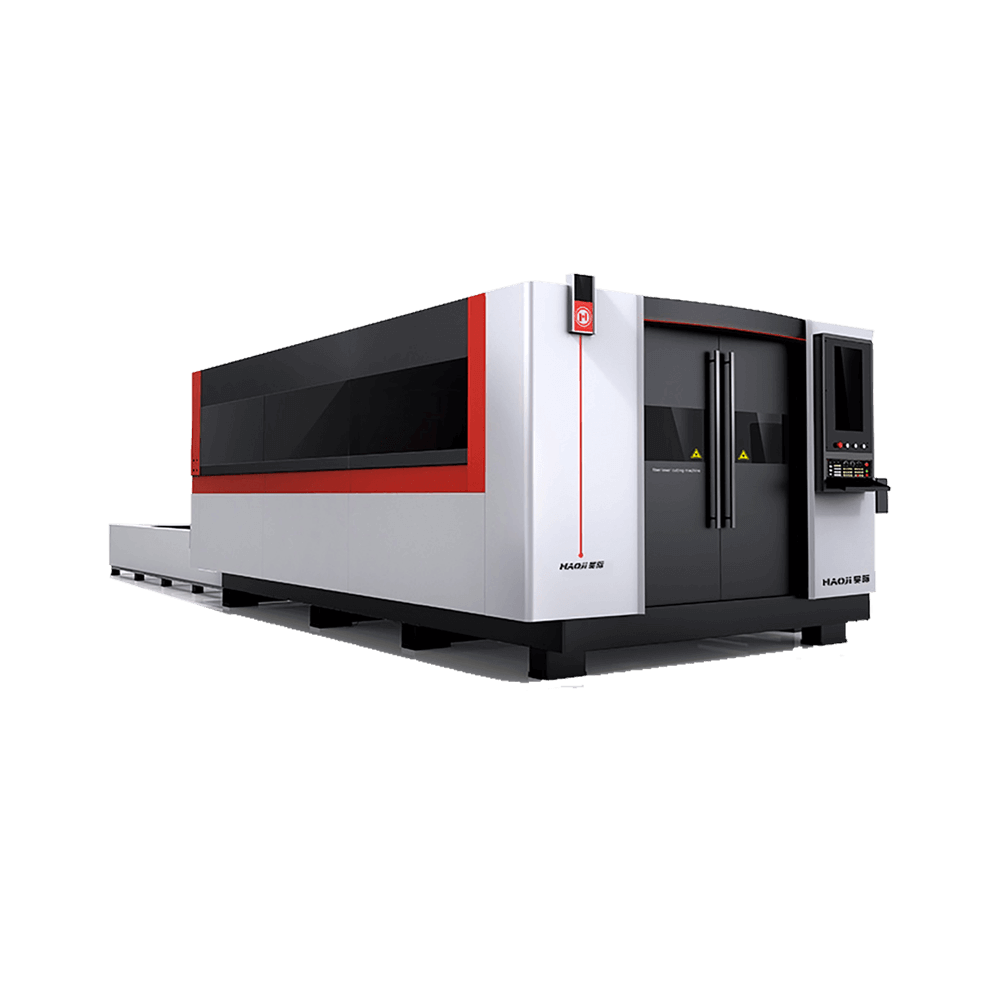

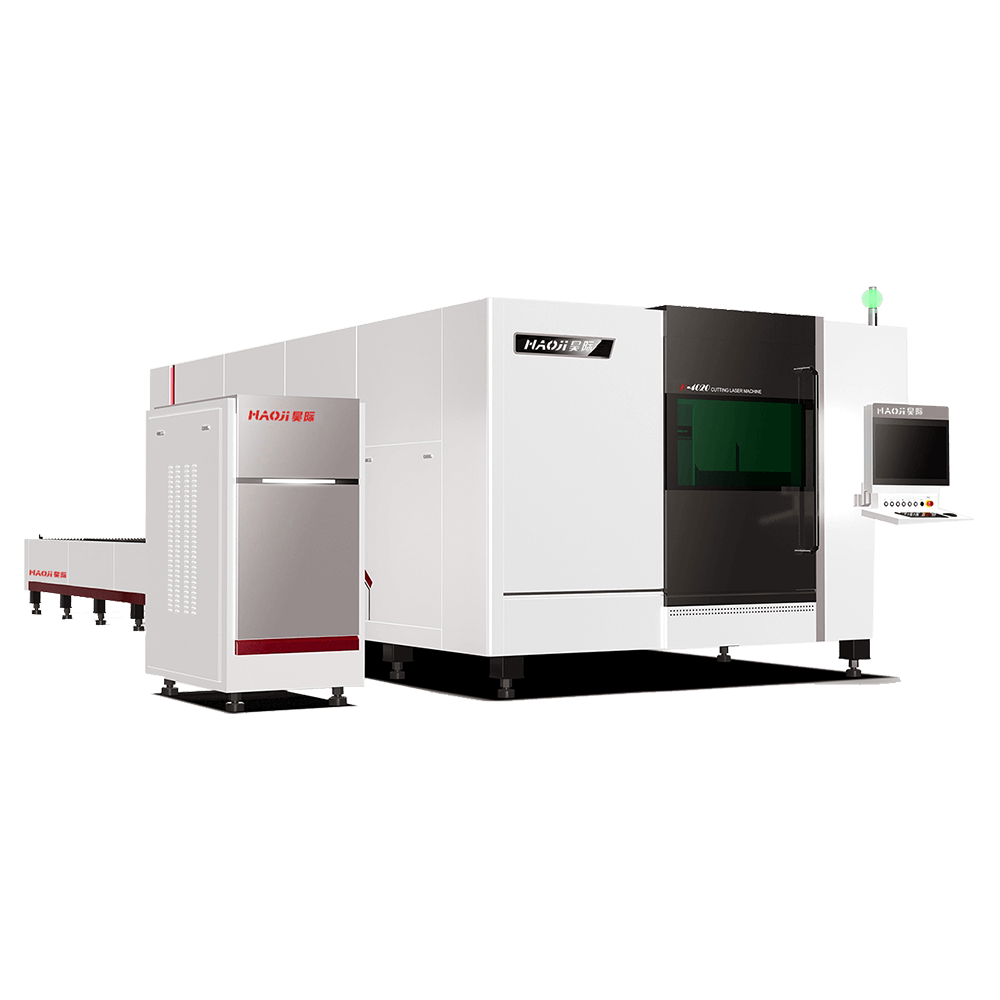

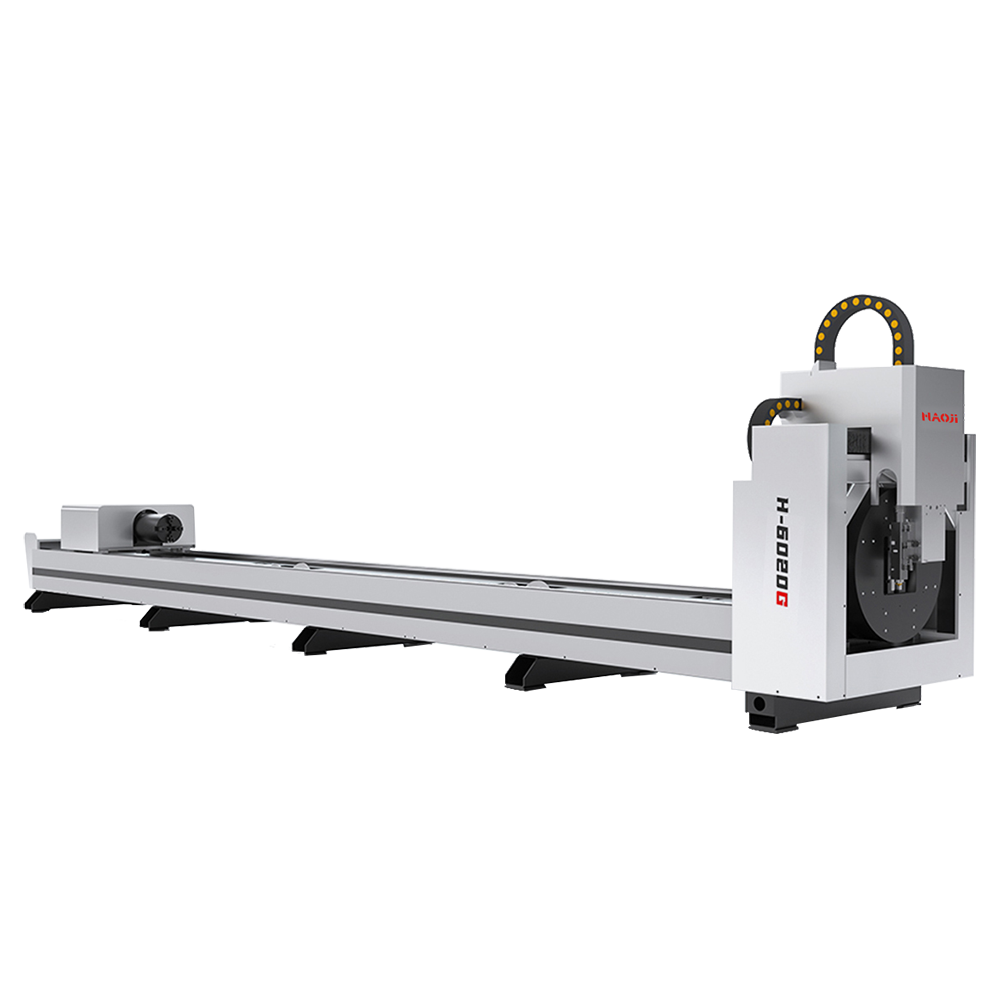

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

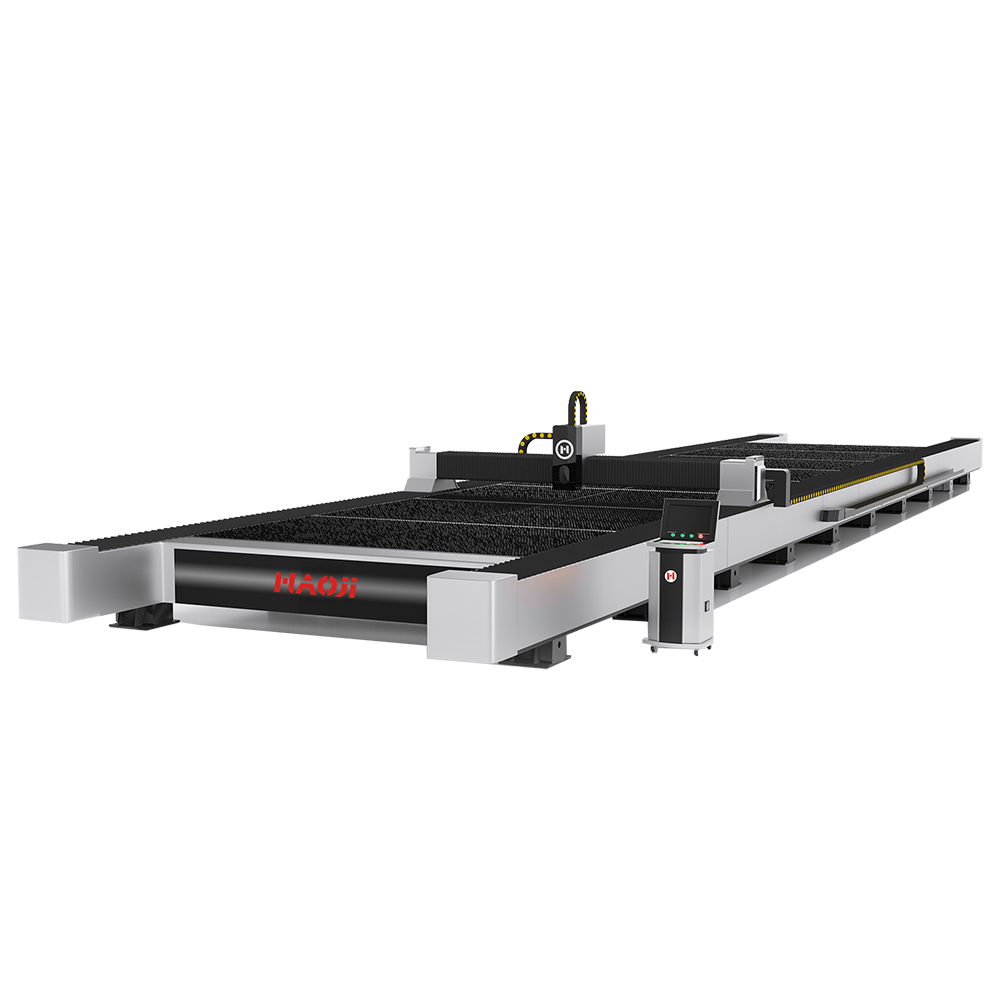

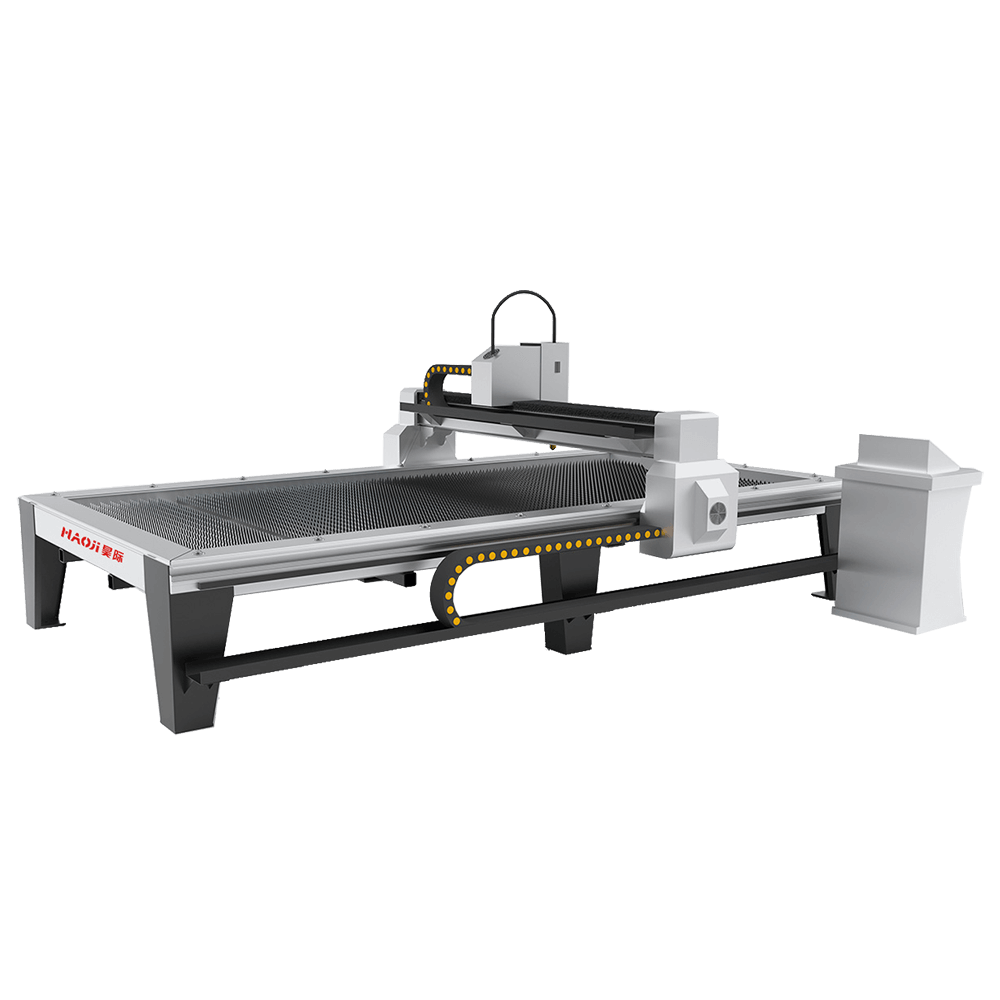

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

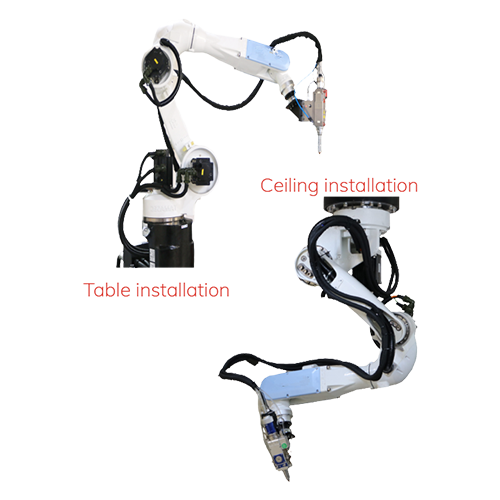

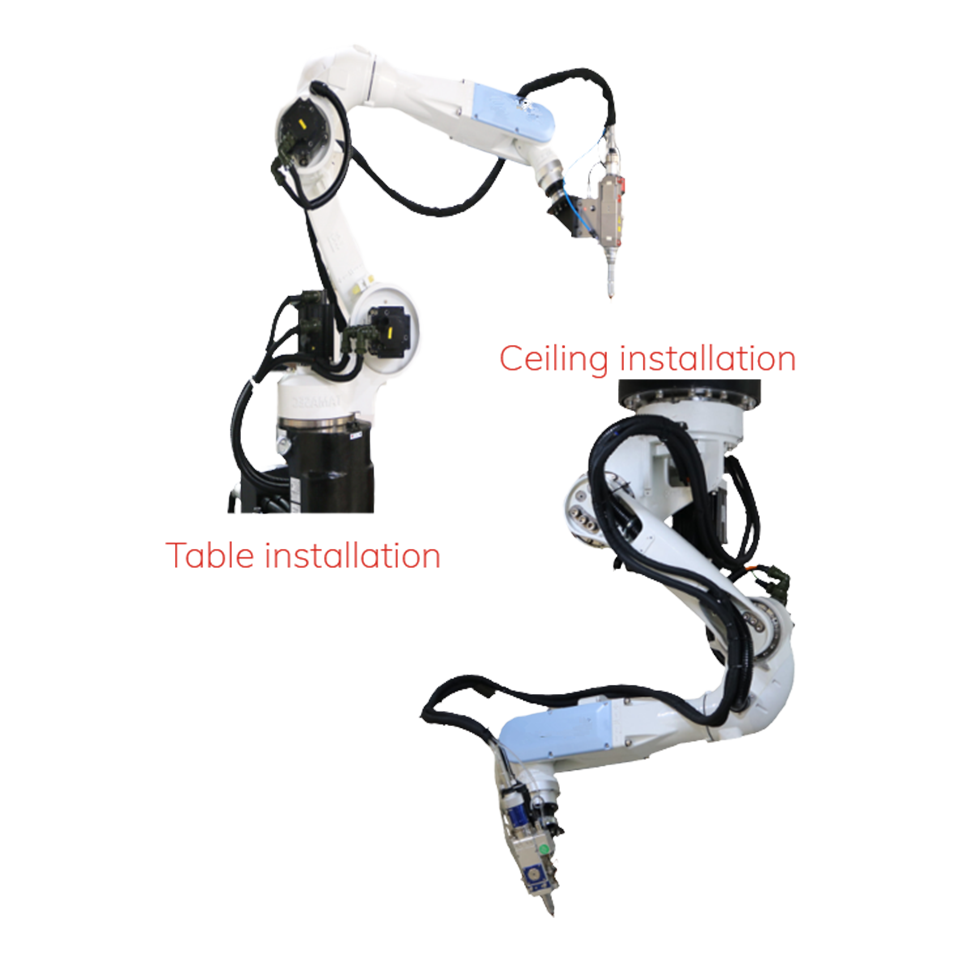

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

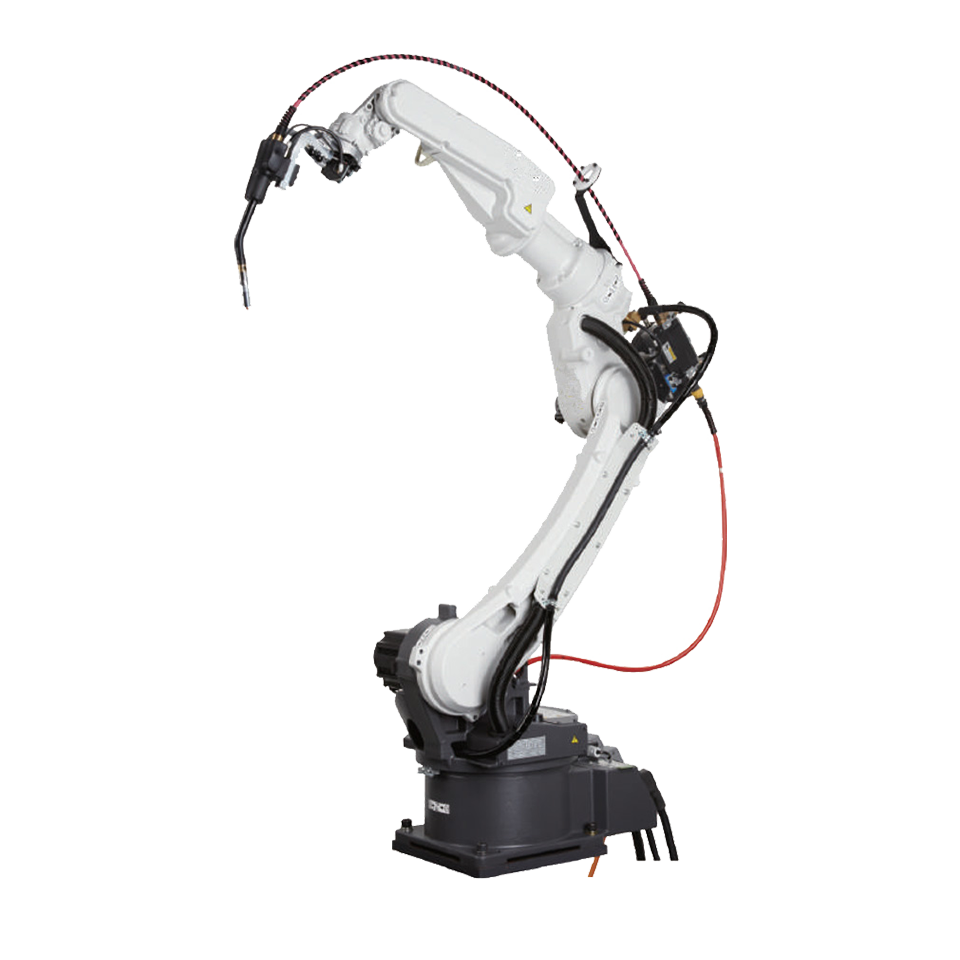

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

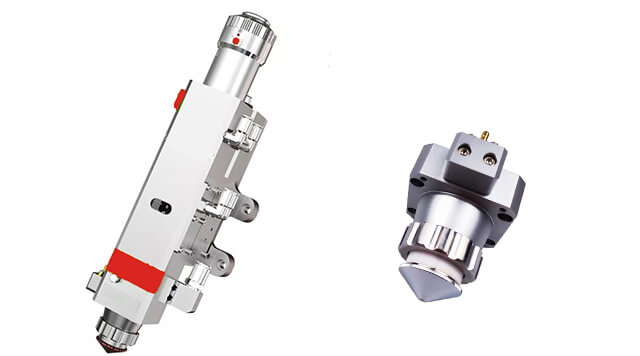

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:06-25 2021

With the increasing temperature in summer, it's necessary for us to understand the summer anti-laser dew maintenance.

Since lasers have higher requirements on the operating environment, in order to protect the lasers in summer and prevent the large temperature difference between the lasers and the outside environment from condensation and damage to the lasers, the following maintenance needs to be done when using the fiber laser machine in summer:

1. Make a separate air-conditioned room for the laser to improve the external working environment of the laser and keep the laser in a dry and constant temperature environment

2. It is recommended that the customer purchase a temperature and humidity meter and place it in the fiber laser engraving machine air-conditioned room to monitor the temperature and humidity in the air-conditioning room.

3. Adjust the temperature of the chiller according to the ambient temperature, set the high temperature to 28-32°C and the low temperature to 25-29°C

4. Strictly implement the switching sequence of optical fiber laser machine.

A. Boot sequence

Turn on the main power switch of the laser and let the case air conditioner or dehumidifier run for more than 30 minutes.

After turning on the laser for 30 minutes, turn on the power switch of the chiller.

B. Shutdown sequence

Turn off the power switch of the chiller.

Turn off the laser power switch.

For more maintenance guidelines, please download from our website.