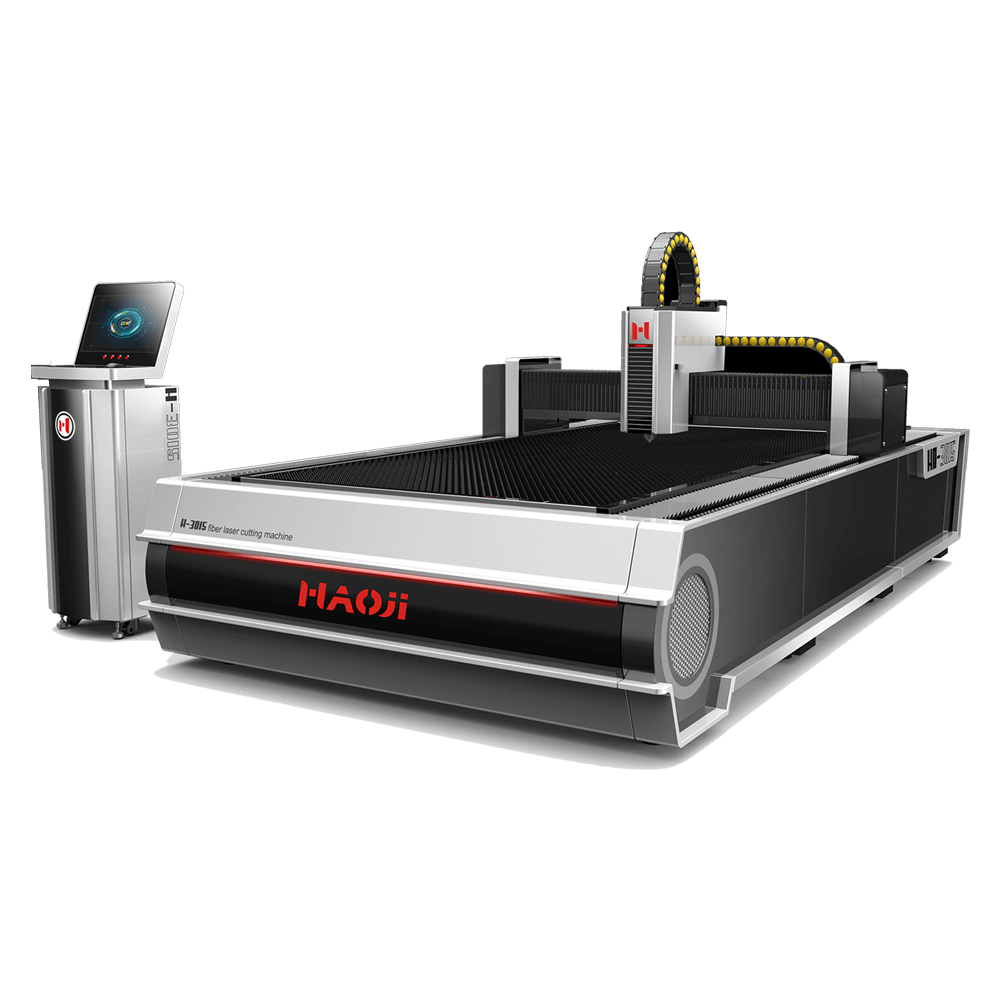

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

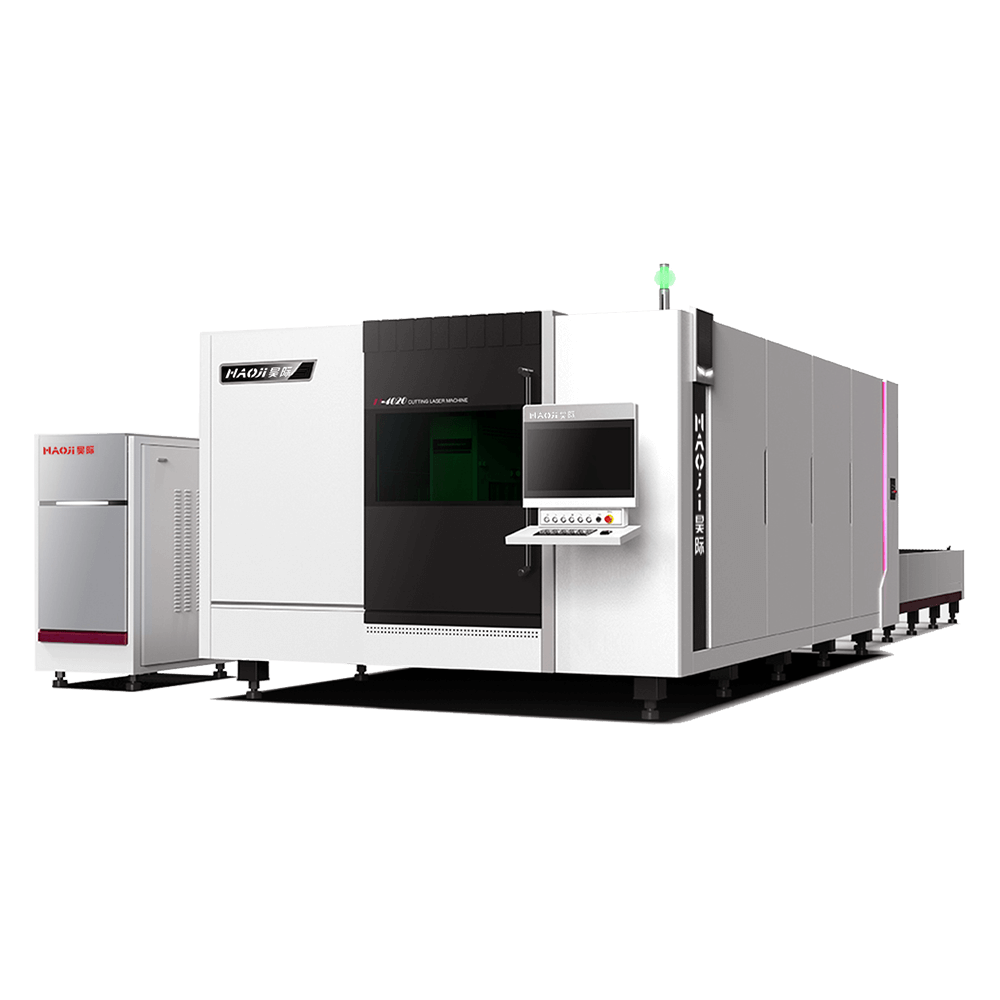

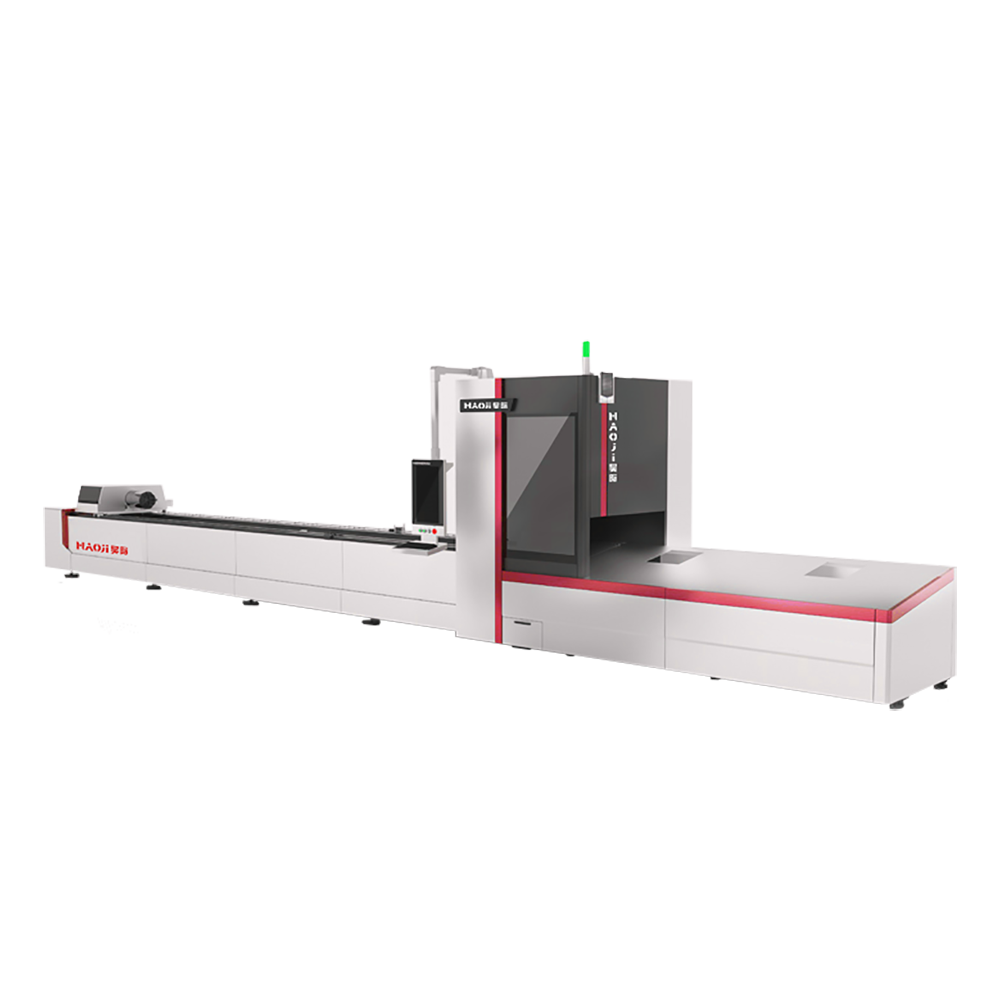

Laser power

1000~20000wMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

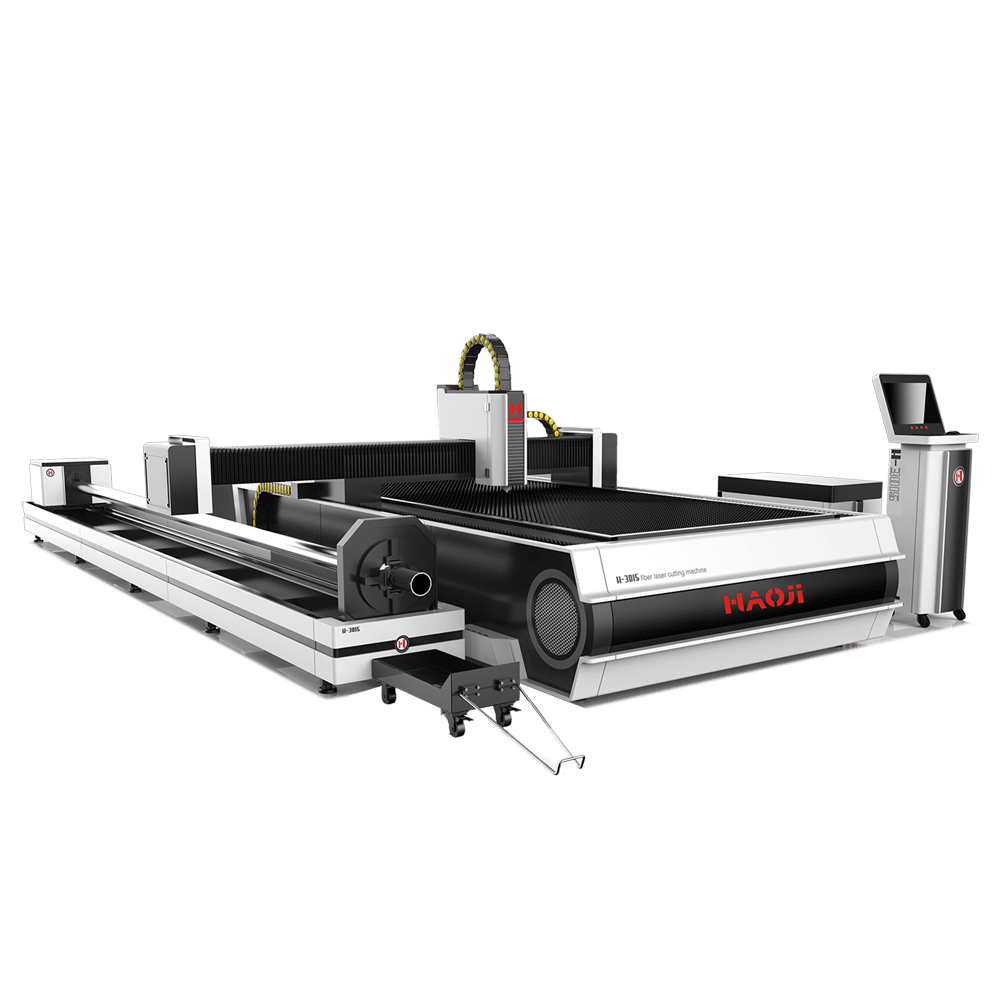

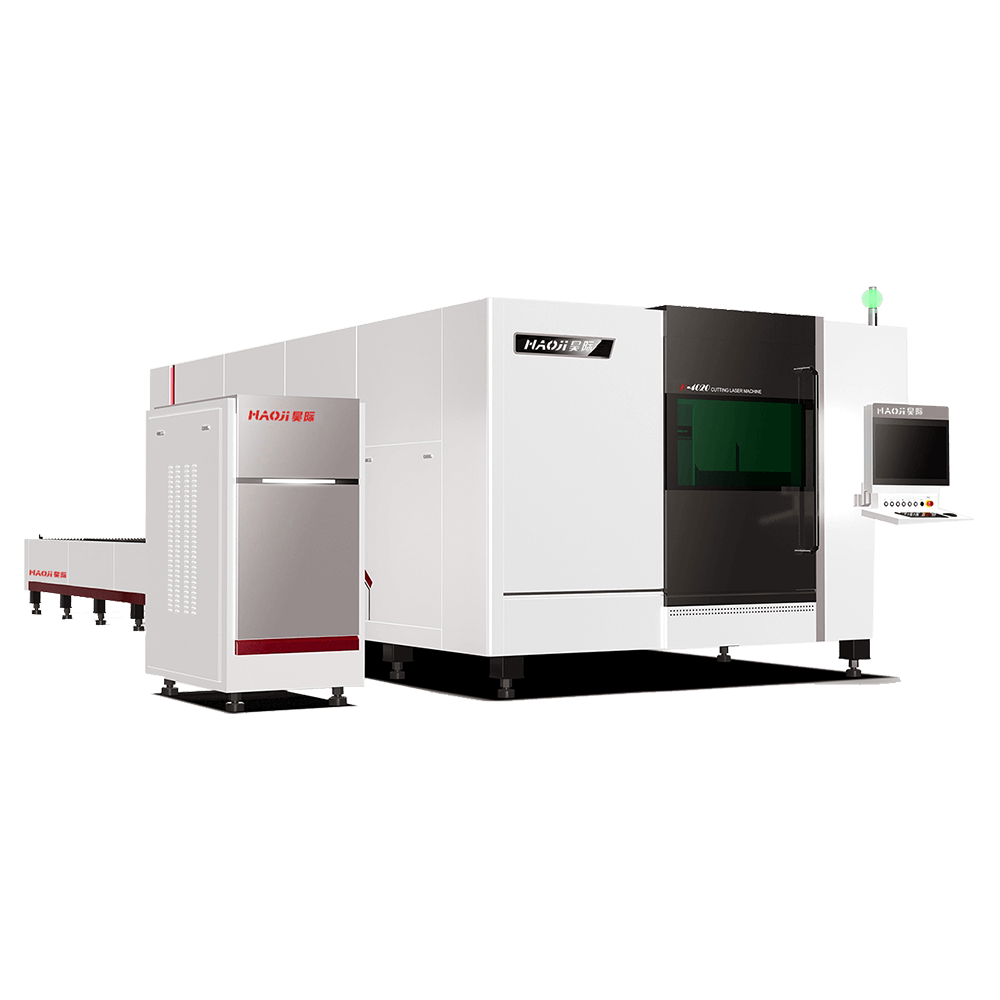

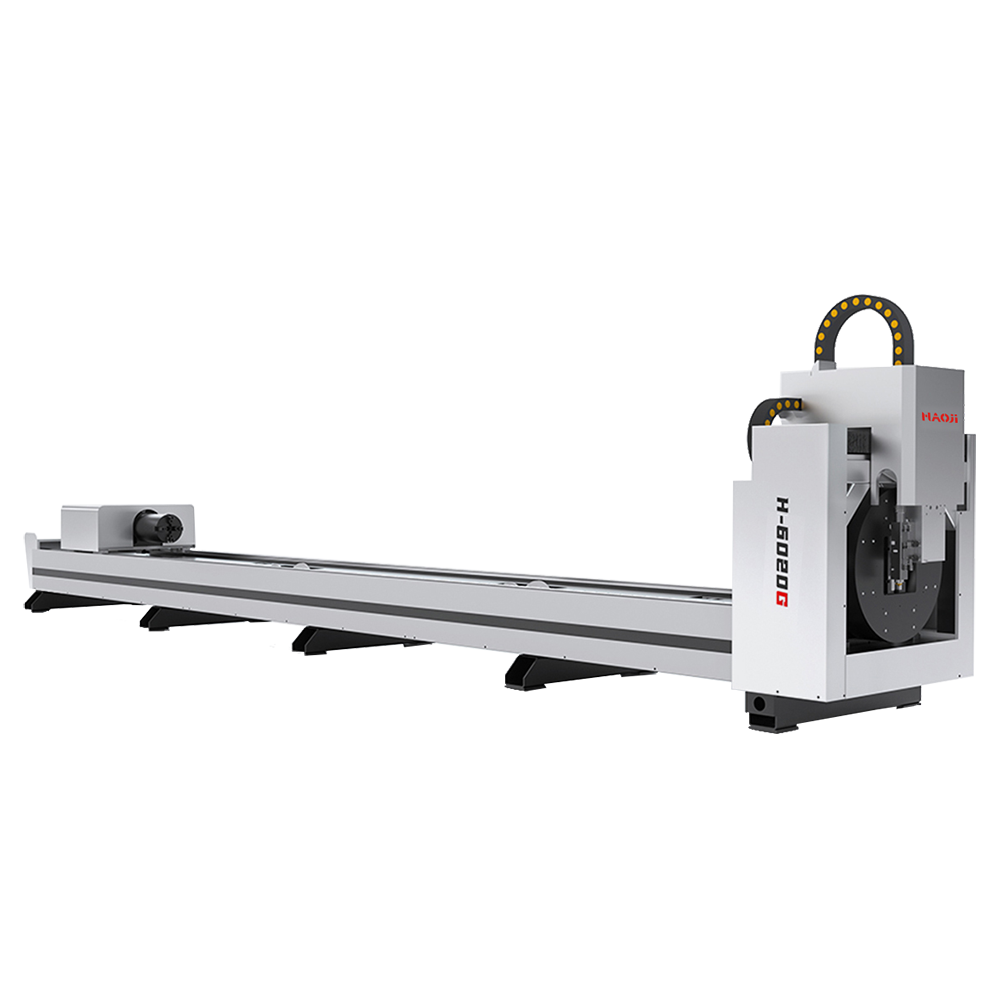

Laser power

1000~20000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

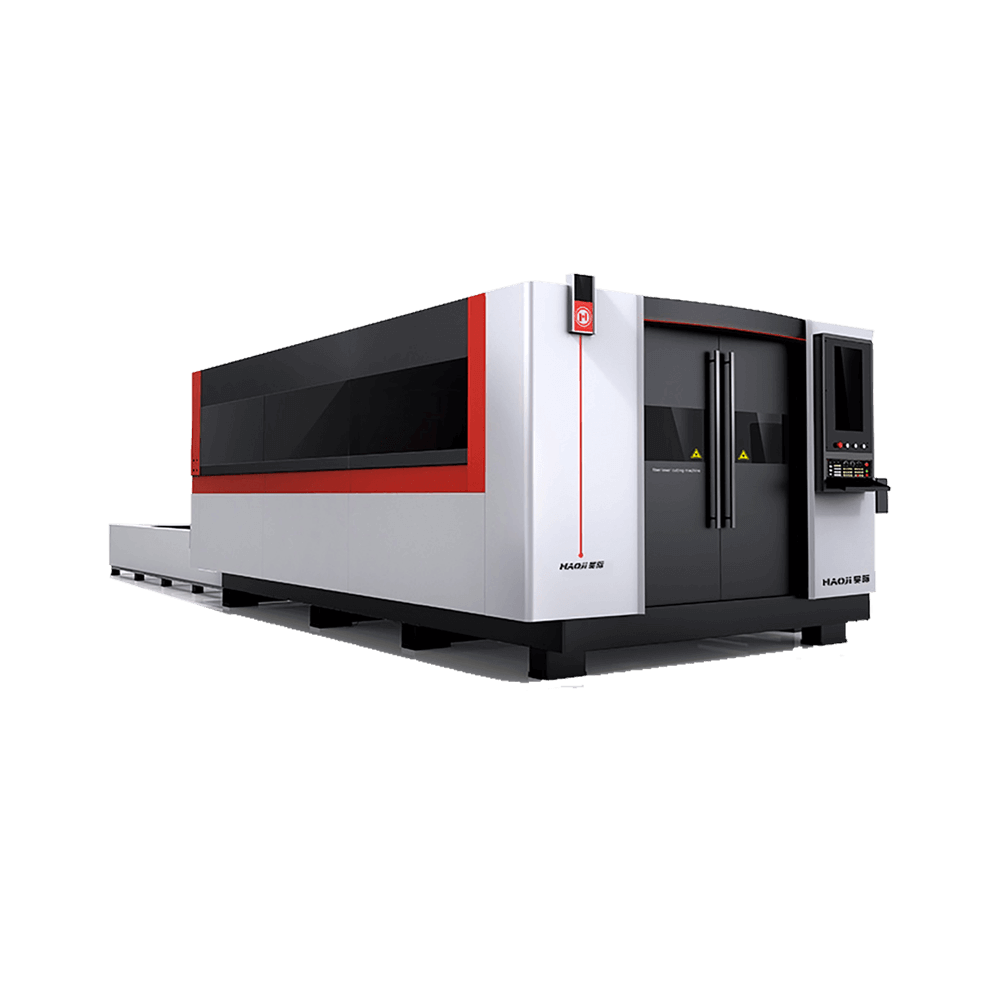

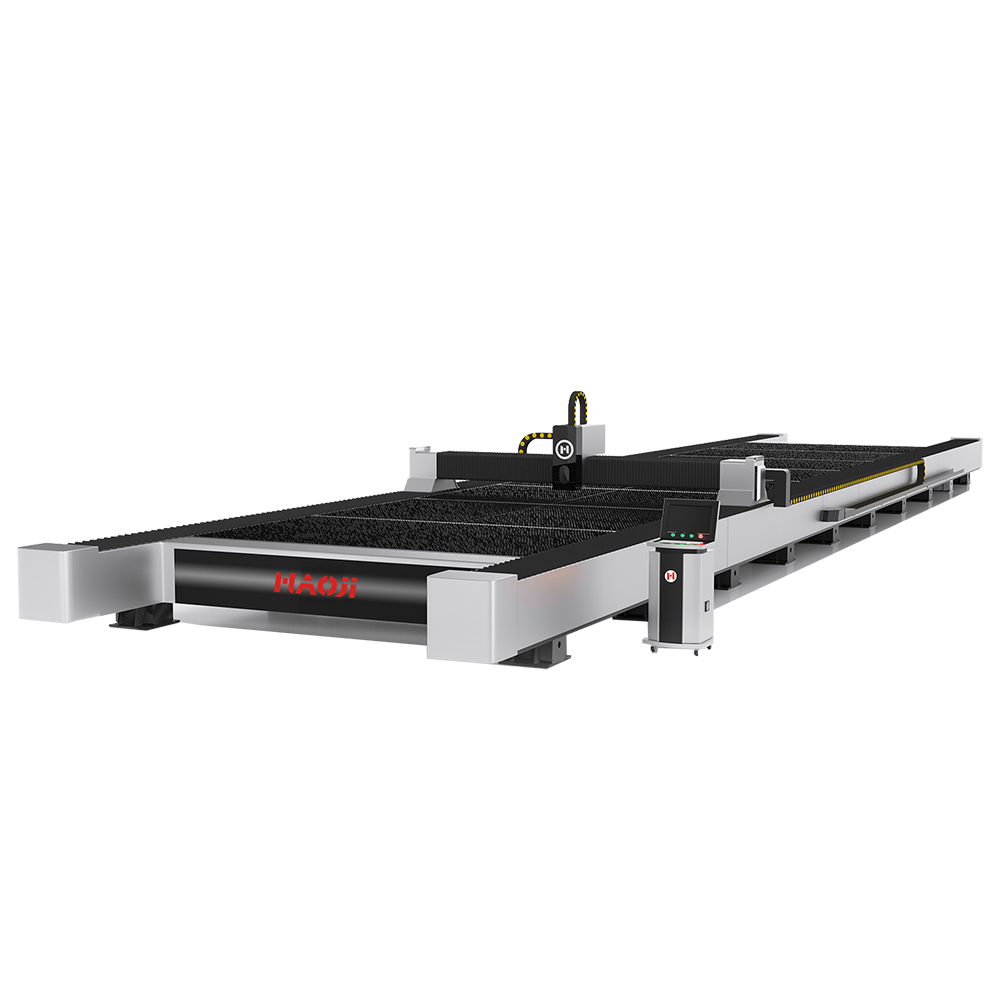

Laser power

10000-35000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-20000WMax. moving speed

200m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-12000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

3000-20000WMax. moving speed

180m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

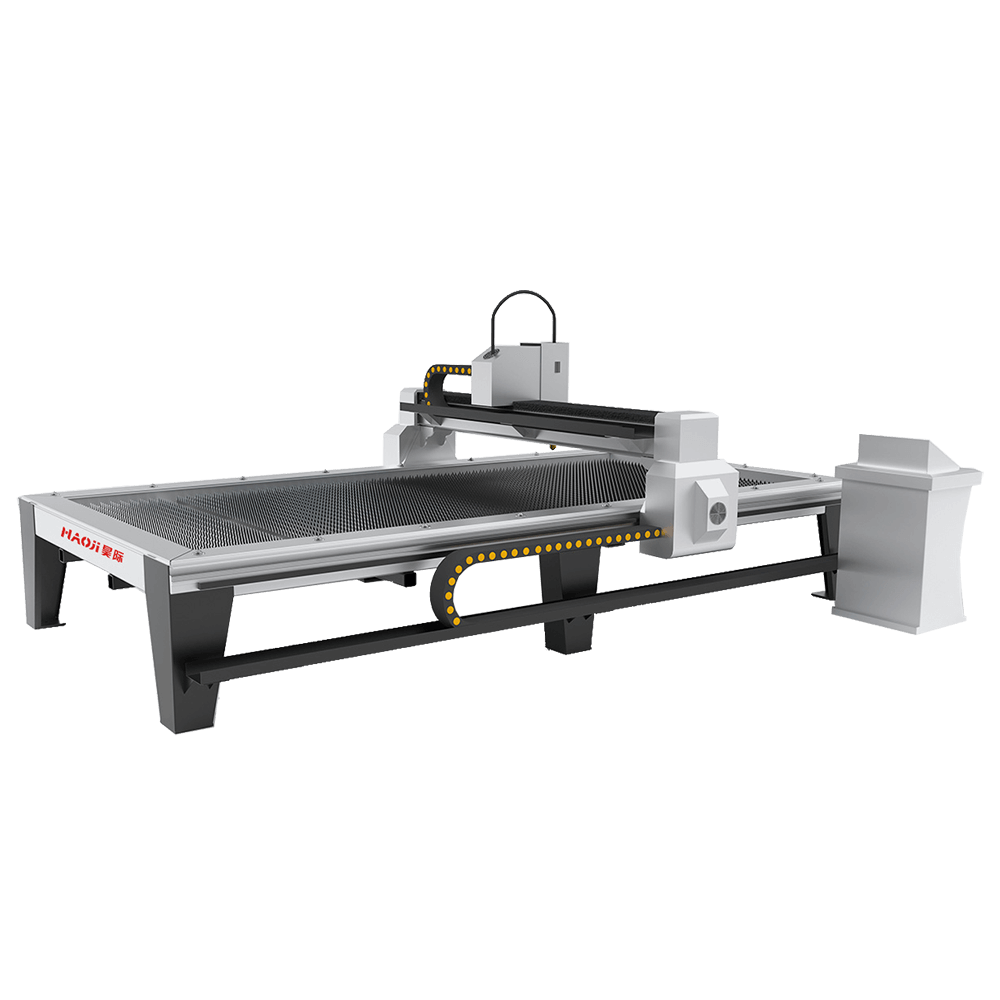

Laser power

/Max. moving speed

100m/minRepeat positioning accuracy

0.03mmBlessing diameter

/

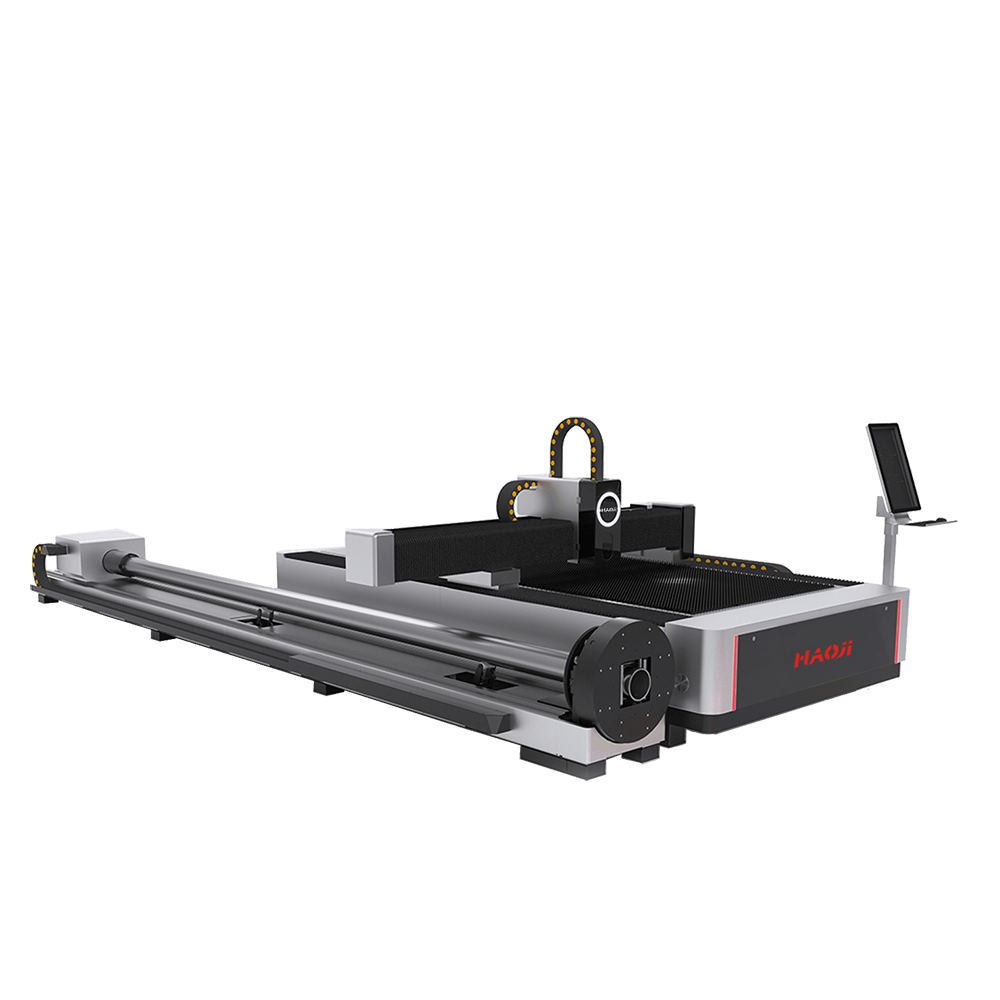

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

1000~3000wMax. moving speed

/Repeat positioning accuracy

0.02mmBlessing diameter

20-220mm

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

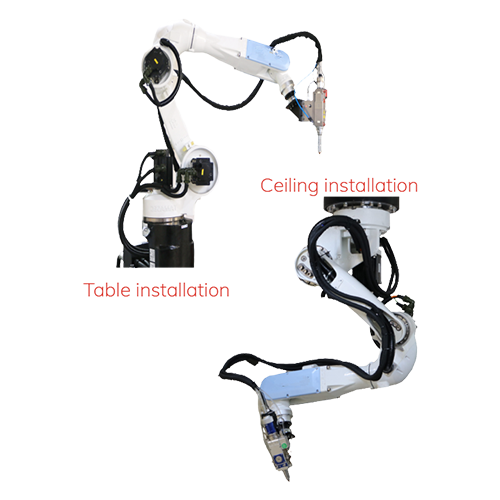

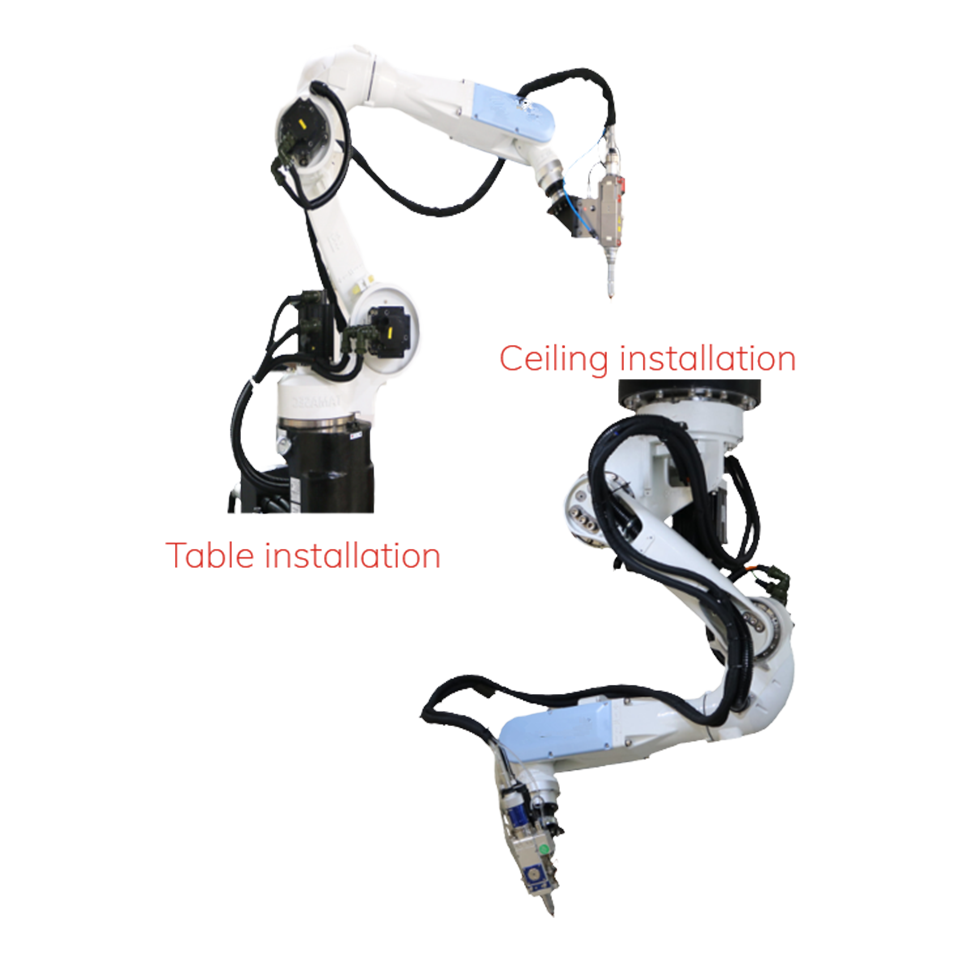

Laser power

1000W-4000WMax. moving speed

140°-600°/sRepeat positioning accuracy

±0.1mmBlessing diameter

/

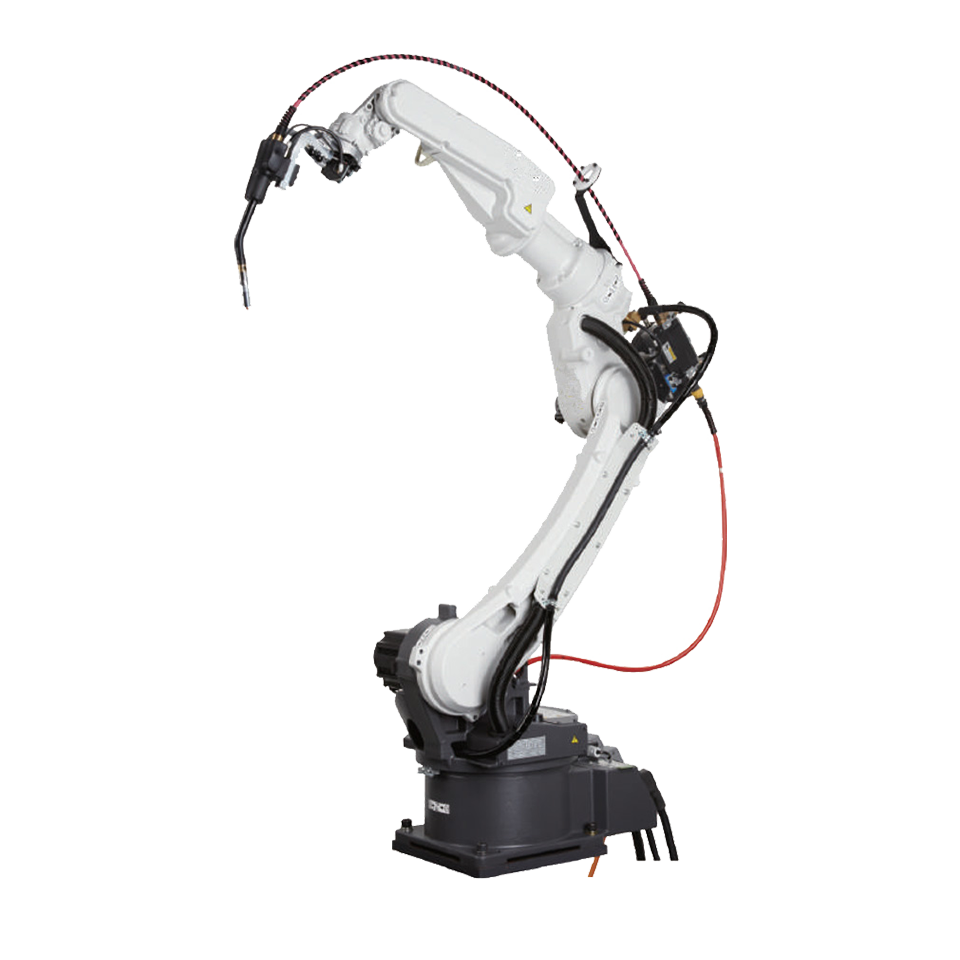

Laser power

1000-3000WMax. moving speed

140m/minRepeat positioning accuracy

0.02mmBlessing diameter

/

Laser power

1000-2000WMax. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

/Max. moving speed

/Repeat positioning accuracy

/Blessing diameter

/

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

Laser power

Max. moving speed

Repeat positioning accuracy

Blessing diameter

TIME:06-16 2021

What is the first thing you see when you go into your home or visit someone else's home? I think most people will notice the sofa first.

Sofa not only has the function such as recreational receive a visitor, it also affecting the decoration style of whole sitting room and even a complete set of houses. A good sofa can leave a deep impression at a glance, so for sofa manufacturers, the choice of sofa fabrics and processing methods is very important.

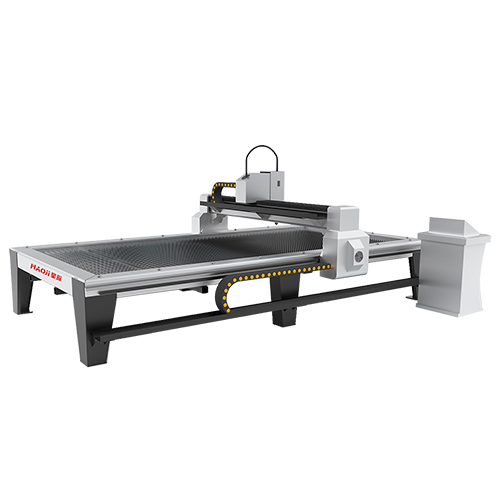

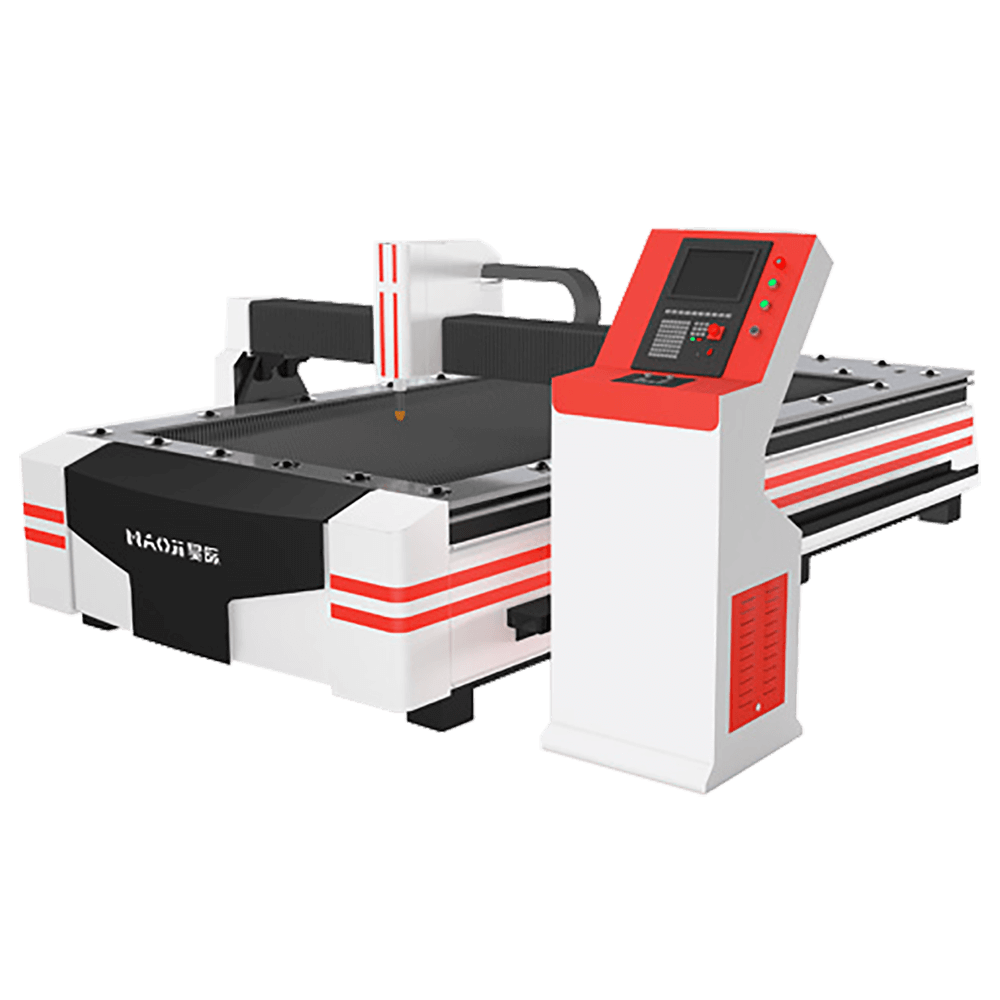

In the past, many sofa manufacturers used manual or tool cutting, which required high technical requirements for operators. Sofa fabric flattening is difficult and time-consuming, it's easy to cause errors and other problems when cutting. Laser cutting bed for sofa fabrics come into being with this opportunity. Common sofa fabrics mainly include leather, artificial leather, cotton and linen, etc.

Fabric laser cutting bed can adapt to a variety of flexible fabric cutting, using computer software to control the cutting path, and the automatic typesetting function can improve the utilization of cloth, prevent material waste.

Match with automatic feeding system, save time and convenient operation. The press rod to ensure the flatness of the material in the feeding process, with high precision and stability to make the sofa fabric cut more exquisite.

The fabric laser cutting bed and laser technology created the beauty of the sofa details and the value of sofa technology, show the strength with quality, interpret ingenuity with details. From details to the whole, from taste to experience, the effect of home decoration has been a qualitative leap.

The process application of the laser cutting bed for textile fabrics: sofa, leather, carpet, curtain, clothing cutting, airbag, car dashboard cover mat and other textile fabric laser cutting.